Table of Contents

Advertisement

Quick Links

Szosa Toruńska Street, No. 32/38, 86-300 Grudziądz, POLAND

Tel +48 56 451 05 00 | Service: + 48 56 451 05 26 |

Read the Operating Manual thoroughly

and follow the safety instructions

contained in it before operating the

machine.

OPERATING MANUAL

FENIX G

SEED DRILL

UNIA Sp. z o.o.

uniamachines.com

To access the Parts Catalogue and Guarantee

Card, scan the QR code on the machine type

plate. Remember to register the guarantee or

service.unia@uniamachines.com

contact your dealer to do so.

VERSION

EN 01/2020

Advertisement

Table of Contents

Summary of Contents for UNIA FENIX G

- Page 1 OPERATING MANUAL FENIX G SEED DRILL UNIA Sp. z o.o. Szosa Toruńska Street, No. 32/38, 86-300 Grudziądz, POLAND Tel +48 56 451 05 00 | Service: + 48 56 451 05 26 | service.unia@uniamachines.com uniamachines.com Read the Operating Manual thoroughly...

- Page 2 FENIX G Operating manual - page 2 -...

- Page 3 FENIX G Operating manual FENIX G Seed drill OPERATING MANUAL Machine identification data: Type Date of production Serial No. This operating manual is an integral part of the machine. It is important that the manual is always in the possession of the user of the machine.

- Page 4 FENIX G Operating manual We pay attention to the fact that the individual properties of the seed material have a large impact on the spreading standard. Therefore, the control data contained in the tables are only indicative and calibration should be carried out before each sowing.

- Page 5 FENIX G Operating manual Duties and Responsibility Follow the instructions in the User Manual The staff operating the machine should be familiar with the general safety regulations applicable when operating agricultural machinery. The operators are obliged to read and follow the instructions and guidelines in this User Manual.

-

Page 6: Table Of Contents

3.1. Loading and Unloading ........................17 3.2. Connecting and Setting the Blower....................17 3.3. Operation and Setting of Metering Unit..................19 3.3.1. Calibration test on the FENIX G seed drill................... 19 3.3.2. Checks during sowing ......................... 21 3.3.3. - Page 7 FENIX G Operating manual Manufacturer’s Liability........................32 Warranty Terms and Conditions......................33 Sowing chart............................. 34 - page 7 -...

-

Page 8: Preface

UNIA Sp. z o.o. will be grateful for your comments to this Manual as well as comments on the machine, its operation and service sent to us. UNIA Sp. z o.o. shall assume no liability for any damages resulting from non- observance of instructions contained in this User Manual. -

Page 9: General Guidelines On Safety And Accidents Prevention

FENIX G Operating manual B.2.12. C.2.23 C.2.20. C.2.11. Do not reach into or step Do not touch the machine Do not open or remove Danger of getting caught into the container of the components until all safety devices while the on the PTO shaft. -

Page 10: Noise And Vibrations

FENIX G Operating manual 13. It is unacceptable to perform mechanical loading using the universal loader, if there is somebody staying in the area of its operation. V. NOISE AND VIBRATIONS The sound pressure level is 77 dB (A). It is measured at the operator's ear level during operation. The tractor’s cabin should be closed. -

Page 11: Restrictions On Traveling On Public Roads

FENIX G Operating manual Maintenance, cleaning and troubleshooting work should be performed basically with the drive turned off, the engine at a standstill and the key removed from the tractor ignition switch. Regularly check the tightness of the bolt nuts and tighten them if necessary! -

Page 12: Preparation For The First Start-Up

FENIX G Operating manual Fig. 1 Retracting the drive wheel 1-drive wheel, 2-securing cotter pins IX. PREPARATION FOR THE FIRST START-UP Follow the steps listed in the chapter before the first start-up of the unit: When preparing the machine for operation, connect it to the tractor first. -

Page 13: General And Commercial Information. Repair During The Warranty Period

FENIX G Operating manual Connect the turbine oil supply hydraulic line to one of the single-acting sockets on the tractor (see Fig. 3). Fig. 3 Hydraulics connection. Mark the type of the socket that is in the free oil return line to the tractor oil tank (screw connection, connector with valve ...). -

Page 14: User Manual

FENIX G Operating manual It is also necessary to comply with relevant accident prevention regulations and other generally accepted rules in the field of technical safety, occupational medicine and traffic regulations. The name plate is located on the rear of the seed hopper. -

Page 15: Technical Data

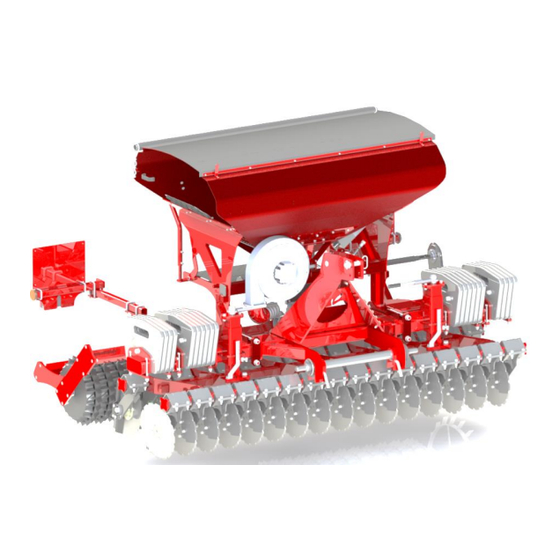

FENIX G Operating manual The FENIX G unit is designed for row sowing of grass seeds and regeneration of meadows. It can also be used for row seeding of other types of seeds (see sowing chart) with parameters defined by the machine specification. - Page 16 FENIX G Operating manual Fig. 4 1 – seed drill frame, 2 – metering unit, 3 - seed transport system with a turbine, 4 - seed hopper with a tarpaulin, 5 - platform with railing, 6 - distributor, 7-drive 8 - track markers, 9 –...

-

Page 17: Using The Machine

FENIX G Operating manual The compacting roller is used to close the grooves in which the seeds are located and to maintain a constant sowing depth. Weights are used for additional weighting of the machine on soils where there is a problem with sinking of the seed coulters. - Page 18 FENIX G Operating manual Speed controller ¾ connector only for connection to the ½ connector for free return. connection to Never connect to hydraulic hydraulic distributors distributors. Fig. 5 Turbine Turbine speed The speed of the turbine is changed by means of a hydraulic controller located in the front part of the machine.

-

Page 19: Operation And Setting Of Metering Unit

(close the screen when over 350 kg/h). For the remaining doses, the screen should be in the open position. 3.3.1. Calibration test on the FENIX G seed drill. Three types of controllers are used to operate the seed drill. - Standard controller for reading basic parameters. - Page 20 FENIX G Operating manual Fig. 7 Scale of the unit 2. Place the container for the seed. Cover of the sample Fig. 8- Calibration test CAUTION: Do not hold the container with your hand during the test! Keep a distance of at least 50 cm from the working unit.

-

Page 21: Checks During Sowing

FENIX G Operating manual 5. Weigh the seeds collected in the container(s). 6. Insert the weight of the seeds into the electronic console. 7. Repeat this step 3 times to get a precise calibration Attention: Detailed information in the controller manual. -

Page 22: Adjustment Of Seed Amount

FENIX G Operating manual 3.3.3. Adjustment of seed Amount When setting the required quantity of sown seed, use the sowing chart and carry out the calibration test then. NOTE! When pouring the seed to the seed container for the first time it should be poured when the metering roller is completely closed (recommended), or at the roller setting by at least 15 % less than indicated in the sowing chart. -

Page 23: Operation Of The Seed Dispenser

FENIX G Operating manual After that, set the dosing roller according to "SETTINGS FOR FINE SEEDS". Fig. 13.1 Fig. 13.2 Fig.13.3 CAUTION! In case of difficulties with setting the dose of fine seeds (e.g. rape in a dose smaller than 2.5kg/ha), we suggest the following solution: while maintaining the above requirements, set the metering roller to twice the required value, extend the small gear (red) from the big gear and mesh it with the other big gear wheel. - Page 24 FENIX G Operating manual 4. We recommend additional blowing the dispenser toothed gear, which clearly affects the extension of its service life. 5. Thorough washing of the dispenser with water under pressure and drying it with compressed air after finishing work is recommended; preserve the metal parts with silicone grease afterwards.

-

Page 25: Filling And Emptying The Seed Hopper And Dispenser

FENIX G Operating manual 3.4. Filling and Emptying the Seed Hopper and Dispenser. The seed hoppers should be filled with seeds by means of mechanical or pneumatic loading devices that are not the equipment of the FENIX seed drill. Loading devices can be purchased in the depots of agricultural machinery. -

Page 26: Track Markers

FENIX G Operating manual 3.5. Track markers. The track markers are alternately folded (right/left) to mark the track on the soil. This marker sets the centre of the tractor's next pass, thus avoiding leaving any unsown field stripes and overlapping passages (Fig. -

Page 27: The Depth Of The Cultivation

FENIX G Operating manual When the machine is at work, never come close to the area of effect of the bout markers 3.6. The depth of the cultivation. For operation, the unit must be set perpendicularly to the ground. Before commencing adjustment, the unit must be mounted on the tractor and lowered to the working position on a flat and hard surface. -

Page 28: Daily Maintenance

FENIX G Operating manual 15. When replacing the knives, pay attention not to replace the right knives with left knives and vice versa. The knife blade should point in the direction of rotation. After installing the knives, check by hand whether the rotors with knives turn without jamming. -

Page 29: Storage

FENIX G Operating manual 4.2. Storage If the machine will not be used for a longer period of time: • Store the machine in a roofed area, if possible. • The machine must be stored in its resting position. All working units should be lowered to the ground to ensure good stability. -

Page 30: Hydraulic System Maintenance And Use

• Damaged or worn hydraulic hoses must be replaced with new ones. • Use only UNIA original hydraulic hoses. • The service life of hydraulic hoses must not exceed 6 years, including the storage time of the machine, for a maximum of two years. Even in the case of proper storage and observance of the instructions for use, hoses, hydraulic hoses and connections are getting old, which is completely normal, hence the limitation of their storage and working time. - Page 31 Failure to comply with the installation specifications. Assembly and disassembly of hydraulic hoses The following instructions must be strictly observed when assembling or disassembling hydraulic hoses: • Use only UNIA original hydraulic hoses. • Always take care of cleanliness. •...

-

Page 32: Lighting Installation

FENIX G Operating manual 4.5. Lighting Installation. Fig. 20 Lighting Installation diagram 1 - left position lamp (not available in mounted machines), 2 - right position lamp (not available in mounted machines), 3 - rear right lamp unit, 4 - left rear lamp unit 5 - connection cable The electrical installation in the FENIX seed drill is of fixed type, provided with two rear lamp units. - Page 33 FENIX G Operating manual The owner is responsible for the operation and maintenance of the machine. The owner of the machine is responsible for the appropriate qualifications of the operators and their knowledge of the operation and maintenance of the machine.

- Page 34 FENIX G Operating manual Sowing chart. Seed material Kg/dm 0,77 0,74 0,68 0,50 0,85 0,81 0,83 0,79 0,36 SCREEN NORMAL SOWING SCREEN SOWING FINE OPEN kg/ha CLOSED SEEDS WYSIEW kg/ha NASION SCALE SCALE 12.0 12.5 11.4 15.3 106 108 87 116 109 109 98 13.7...

- Page 35 FENIX G Operating manual REMARKS AND COMMENTS UNIA Sp. z o.o. Brzeg production plant Fabryczna Street, No. 2 PL 49 – 301 BRZEG, POLAND tel. + 48 77 444 45 86 fax. + 48 77 416 20 83 Service tel. + 48 77 444 45 11 uniamachines.com...