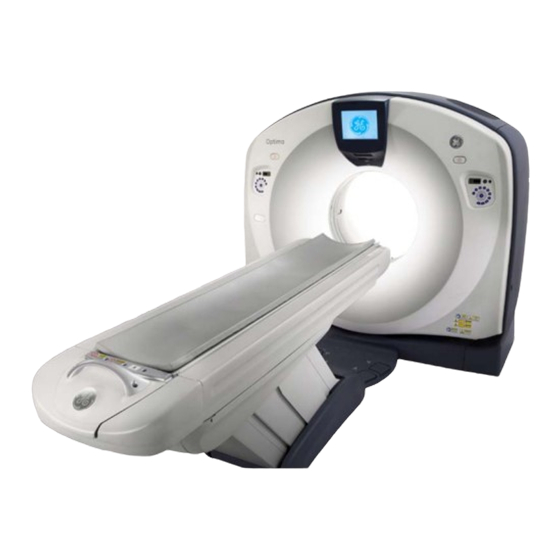

Summary of Contents for GE Optima CT680 Series

- Page 1 Optima CT680 Series and Optima CT670 Installation Manual (Book 1 of 2) OPERATING DOCUMENTATION 5472001-1EN Rev. 6...

- Page 2 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Book 1 of 2: Mechanical Installation Pages 1 - 206 Effectivity The information in this manual applies to the following Optima CT Systems: •...

- Page 3 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL IMPORTANT PRECAUTIONS LANGUAGE Това упътване за работа е налично само на английски език. ПРЕДУПРЕЖДЕНИЕ • Ако доставчикът на услугата на клиента изиска друг език, (BG) задължение...

- Page 4 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL ADVARSEL Denne servicemanual findes kun på engelsk. • Hvis en kundes tekniker har brug for et andet sprog end engelsk, er det (DA) kundens ansvar at sørge for oversættelse.

- Page 5 Serviceanleitung gelesen und verstanden zu haben. • Wird diese Warnung nicht beachtet, so kann es zu Verletzungen des Kundendiensttechnikers, des Bedieners oder des Patienten durch Stromschläge, mechanische oder sonstige Gefahren kommen. ΠΡΟΕΙ∆ΟΠΟΙΗΣΗ Το παρόν εγχειρίδιο σέρβις διατίθεται μόνο στα αγγλικά.

- Page 6 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 경고 본 서비스 매뉴얼은 영어로만 이용하실 수 있습니다 . • 고객의 서비스 제공자가 영어 이외의 언어를 요구할 경우 , 번역 서비스 (KO) 를 제공하는 것은 고객의 책임입니다 .

- Page 7 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL ATENÇÃO Este manual de assistência técnica só se encontra disponível em inglês. • Se qualquer outro serviço de assistência técnica solicitar este manual (PT-PT) noutro idioma, é...

- Page 8 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL ATENCION Este manual de servicio sólo existe en inglés. • Si el encargado de mantenimiento de un cliente necesita un idioma que (ES) no sea el inglés, el cliente deberá...

- Page 9 In performing all electrical work on these products, GE will use its own specially trained field engineers. All of GE’s electrical work on these products will comply with the requirements of the applicable electrical codes.

- Page 10 GE Healthcare Radiation Safety Officer to use radioactive materials to service this equipment. GE Healthcare is required to notify the applicable U.S. state agency PRIOR to any source service event involving pin source handling. See NUC/PET radioactive material guides for specific instruction or contact your EHS Specialist.

- Page 11 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Revision History Date Reason for change Sep 04, 2017 Add the Optima CT670 product name May 05, 2017 Chapter 2, Section 3.3.2: Added HP LCD connection information Chapter 2, Section 3.4: Added Figure 2-12 for z840 rear panel...

- Page 12 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Page 12 Revision History...

-

Page 13: Table Of Contents

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Table of Contents: Book 1 Preface Publication Conventions ..................21 Section 1.0 Safety & Hazard Information ................21 Text and Character Representation................. 21 Graphical Representation .................... - Page 14 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Time & Personnel......................34 Tools and Test Equipment ....................34 Safety ..........................34 Floor Preparation ......................34 4.4.1 Preparation......................34 4.4.2 Flooring ......................34 Room Preparation ......................

- Page 15 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 10.2 Tools and Test Equipment....................63 10.3 Procedures ........................63 10.3.1 Draw Table Reference Lines ................63 10.3.2 Cradle Center Procedure..................65 10.3.3 Install the Table Cradle Laser Alignment Plates..........66 10.3.4 Level and Center the Table to the Gantry............

- Page 16 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 17.3.2 Peripherals Placement ..................96 Section 18.0 Seismic Mounting ............... 97 18.1 Time and Personnel ......................97 18.2 Procedures........................97 18.2.1 Console ......................97 18.2.2 Power Distribution Unit..................

- Page 17 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 8.1.1 Panel - 380 - 480VAC Mains “TS1” Input Power Connection......126 8.1.2 Panel - Circuit Breakers..................126 8.1.3 HVDC Connection .................... 127 8.1.4...

- Page 18 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Procedures........................150 2.3.1 Console Side Covers ..................150 2.3.2 Console Top Cover ..................151 2.3.3 Console Front Cover ..................152 Section 3.0 Table Cover Installation (GT1700V) .......... 153 Side Covers........................

- Page 19 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Procedures ........................169 1.3.1 Gantry Scan Window ..................169 1.3.2 Side Cover Removal..................170 1.3.3 Top Cover Removal..................171 1.3.4 Gantry Front Cover ................... 172 1.3.5...

- Page 20 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Page 20 Table of Contents...

-

Page 21: Optima Ct680 S

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Preface Publication Conventions Please become familiar with the conventions used within this publication before proceeding. Section 1.0 Safety & Hazard Information Text and Character Representation Within this publication, different paragraph and character styles have been used to indicated potential hazards. -

Page 22: Graphical Representation

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL NOTICE Notice is used when a hazard is present that can cause property damage but has absolutely Equipment no personal injury risk.They can include: Damage •... -

Page 23: Publication Conventions

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 2.0 Publication Conventions General Paragraph and Character Styles Prefixes are used to highlight important non-safety related information. Paragraph prefixes (such as Purpose, Example, Comment and Note) are used to identify important but non-safety related information. -

Page 24: Computer Screen Output/Input Character Styles

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Headers and footers in this publication are designed to allow you to quickly identify your location. The document’s part number and revision number appears in every header on every page. Odd numbered page footers indicate the current chapter, its title, and current page number. -

Page 25: Position Subsystems

5.) Never modify the system in whole or part without prior written approval by GE Healthcare. 6.) Do not change, add or remove any system accessory without prior written approval of the vendors local service manager. -

Page 26: Introduction

4.) Use the laser tool to position the table relative to the gantry. 5.) Level the table to the gantry, and anchor the system. 6.) Complete the mechanical installation section of GE Form e4879. Note: Use the template to position the system. Use the gantry and table to locate and drill the anchor holes. -

Page 27: Required Common Tools And Supplies

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Required Common Tools and Supplies The following tools and supplies should be included in the standard CT installation tool kit. The tools listed represent the minimum tools required for installing this CT scanner. - Page 28 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Electrical Tools • DVM capable of reading 0.5 ohms or less • Dale 600 or 601 Leakage meter or equivalent • Continuity Tester •...

- Page 29 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL GE Tools • System Alignment Kit (p/n 5148193 or p/n 5272090) (This tool may not be available via the tool pool in some areas.)

-

Page 30: Section 3.0 Delivery Procedure

In general, construction sites fail to meet the required specifications for system delivery, and GE Healthcare does not recommend such installations, as they can result in delays, increased costs, and possible damage to the system. When construction-site delivery proves unavoidable, the installation falls into one of two categories: •... -

Page 31: Construction Site With Completed Radiology Area

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 3.4.1 Construction Site with Completed Radiology Area This type of site consists of a finished, dust-free, occupancy-ready radiology suite at a site with ongoing construction in other areas, but with no remaining construction in or around the scan suite area. -

Page 32: Working With The Mover

14-day period. To file a report: • Call 1-800-548-3366 and use option 8. • Fill out a report on http://egems.med.ge.com/edq/home.jsp • Contact the local service coordinator for more information on this process. Rev. June 13, 2006 Page 32 Section 3.0 - Delivery Procedure... -

Page 33: A1 Breaker

Service clearances MUST be met to continue. 3.) A customer Anchoring Plan is required if there is anything other than a 101.6 mm (4 in.) (minimum) concrete floor. GE employees shall only install the anchors supplied with this system. -

Page 34: Section 4.0 Layout The Floor Template

2 (FE or mechanical supplier) Tools and Test Equipment • Standard Install Tool Kit • Install Support Kit • GE Site Print • Floor Template for your system • Chalk line • China marker or wax marking pencil, or equivalent •... -

Page 35: Room Preparation

2.) Tape the templates together, making sure that the table and gantry center lines are matched. Then tape the template to the floor. 3.) Recheck the position of the gantry in the room per the GE print. If everything matches the GE print, continue. If not, realign the templates to match the print. - Page 36 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure 1-2 Gantry Tube Change Cart 5.) Prior to removing this template, check floor levelness, as shown in Figure 1-3. 6.) Position the laser from the install kit on the template behind the table base and turn it on to project a horizontal beam across the floor template area.

- Page 37 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL NOTICE Positioning requires cutting eight (8) holes in the floor covering. Before you drill or cut any flooring, make sure that you have discussed this issue with the customer, and that the appropriate hospital personnel have approved the location of the table/gantry.

- Page 38 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 11.) Cut tiles (or other resilient flooring) around all holes punched in the template for the gantry and table. Note: A fast way to remove flooring is to use a 4 in. hole saw with a 1/4 in. masonry bit to cut through the flooring at each leveler pad location.

-

Page 39: Section 5.0 Install The Gantry

Reqs 2 (FE or mechanical supplier) Tools and Test Equipment • Standard Install Tool Kit • Install Support Kit • GE Site Print • Installation Manual • Gantry Adjuster Tool, P/N 2107863 • Spanner Wrench, P/N 2110003 • PPE (hand protection, foot protection, face shield, eye protection, personal dosimeter) -

Page 40: Procedure

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Procedure 1.) Position the gantry over the floor cutouts appropriately. a.) Locate the four (4) leveling pads, and position each of them beneath its associated adjuster. - Page 41 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure 1-6 Gantry and Table Base Leveling Pads (Starting Positions) NOTICE Gantry dollies weigh approximately 250 lbs each. Exercise caution when removing dollies so as to not damage the floor covering.

- Page 42 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 8.) Remove the four (4) gantry shipping bolts, using a 1½" socket. Note: Bolt requires a 1-½" socket Note: Leave this locking ring...

-

Page 43: Section 6.0 Level The Gantry

2 (FE or mechanical supplier) Tools and Test Equipment • Standard Install Tool Kit • Install Support Kit • GE Site Print • Gantry Adjuster Tool, P/N 2107863 • Spanner Wrench, P/N 2110003 • Procedure The gantry uses 2 bubble levels that are permanently mounted to machined surfaces on the stationary base to tell when it is level. - Page 44 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 1.) Loosen all adjuster lock rings (use a spanner wrench or large channel lock pliers). 2.) Systematically turn each of the gantry’s adjusters (locations 1, 2, 3 and 4 in...

- Page 45 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Correct level is 100% of bubble within small circle Incorrect level is less than 100% of bubble within small circle Bubble Incorrect < 100%...

-

Page 46: Section 7.0 Gantry Bearing Gap Inspection

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 7.0 Gantry Bearing Gap Inspection All CT systems require a gantry bearing gap inspection before starting electrical calibration. All international gantries are shipped in a wooden shipping crate that should not be removed until it arrives at the installation site. -

Page 47: Procedure

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL The gap to inspect is shown in Figure 1-14 next to the serial number. Bearing Surface Figure 1-14 Gantry Bearing On most systems, a change in the bearing gap does not cause the gantry to make unusual sounds, unless the gap is severe. -

Page 48: Finalization

Gap is good (right) Finalization 7.5.1 Mechanical Installers If the Bearing Gap Inspection passes, complete the sign-off on the GE Form e4879, Installation Data verification form, that this inspection was completed. If the Bearing Gap Inspection fails, contact your site FE. 7.5.2... -

Page 49: Fe Inspection Completion

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL If no damage is found, close this dispatch and continue with the electrical calibration procedures. If the system is damaged, go to the Equipment Delivery Quality web site and follow their instructions. -

Page 50: Section 8.0 Install Gantry Alignment Laser And Bracket

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 8.0 Install Gantry Alignment Laser and Bracket Time and Personnel Required Persons Preliminary Procedure Finalization Reqs 2 (FE or mechanical supplier) Tools and Test Equipment •... - Page 51 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 4.) Remove two (2) bottom bore cover screws and loosen the top bore cover screw. Figure 1-19 Bore Cover Screws 5.) Slide the bore cover about 5 cm (2 in.) so that the laser tool can be attached.

- Page 52 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Do not drop bolts or the bar on the collimator faceplate. Attach the bar as shown in Figure 1-21. Using a minimum 223 mm (9 in.) level placed on the attached bar, level the bar by rotating the gantry.

- Page 53 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 9.) When pressed, the ON button steps through four different beam profiles and "Self-Leveling Off". Press the ON button until the "|" beam shows. It is used for this operation.

-

Page 54: Section 9.0 Table Installation (Gt1700V)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 9.0 Table Installation (GT1700V) Note: For Lite Table Installation, refer to Section 10.0. Time and Personnel Required Persons Preliminary Reqs Procedure Finalization 2 (FE or mechanical supplier) 1.5 hours labor on-site... - Page 55 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 2.) Using a chalk line, mark a table center line on the floor along the laser light shining on the floor. 673 ± 6 mm (26.5" ± 0.25") Gantry Base Reference line for Table 673 mm (26.5") Z-distance...

- Page 56 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 1.) Remove all the transportation packaging and boxes, except dollies, from the table. (See Figure 1-27.) Leave a layer of packing material on the cradle to protect the cradle from damage.

- Page 57 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 9.3.3 Table Cover Removal 1.) Remove the table right side cover, as shown in Figure 1-31. a.) Removing the two screws on each end of the underside of the long side cover of the table.

-

Page 58: Removing The Accessory Rail Strip

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 9.3.4 Removing the Accessory Rail Strip 1.) Remove the accessory mounting strip attached on each side of the cradle using a small flat blade screw driver. -

Page 59: Level And Center The Table To The Gantry

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 3.) Lower the table to the floor using the dollies, making sure to maintain the 673mm (26.5 in.) distance. Reference line for table Z-distance... - Page 60 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Note: Step 4 through Step 7 are for perpendicular positioning of the cradle to the gantry. 3.) The table on the dollies should be resting on the floor, and the laser beam visible on the cradle.

- Page 61 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL CAUTION Potential for Injury. In the ship position, the table tips easily! DO NOT lean on the table! The shipping bracket should still be in place! 9.) Place the bubble level on the table base.

-

Page 62: Tighten The Lock Rings

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 9.3.7 Tighten the Lock Rings 1.) Re-check gantry bubble levels. 2.) Re-check that each of the eight adjuster is loaded by attempting to turn it. -

Page 63: Section 10.0 Table Installation (Lite Table)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 10.0 Table Installation (Lite Table) 10.1 Time and Personnel Required Persons Preliminary Reqs Procedure Finalization 2 (FE or mechanical supplier) 1.5 hours labor on-site 10.2... - Page 64 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 2.) Remove all the transportation packaging and boxes, except dollies, from the table. 3.) Wheel the table to its approximate position relative to the gantry, using the marks made earlier.

-

Page 65: Cradle Center Procedure

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL To adjust two leveling pads at rear end of table, please insert the screw driver into the hole located on the bolt then rotate the bolt, refer to the Figure 1-41. -

Page 66: Install The Table Cradle Laser Alignment Plates

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 2.) Release a latch by pushing a bracket to move the cradle by hands. See Figure 1-43. Original Position Release Position Release Lever Figure 1-43 Release the Cradle 3.) Center the cradle on the drive rollers assembly by pushing the cradle into the gantry to its... -

Page 67: Level And Center The Table To The Gantry

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Tighten adjustment knob. 2.) Install the rear table laser alignment which has a cross target to the back of the cradle. a.) Loose adjustment knob to make the slot plate free. -

Page 68: Procedure

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 10.3.4.3 Procedure NOTICE Avoid leaning on the cradle during this procedure. DO NOT pin the gantry during this alignment process. This procedure is for systems mounted on 102 mm (4 in.) concrete floors only! -

Page 69: Section 11.0 Drill The Anchor Holes

Notes to Mechanical Installers Note 1: Basic Anchoring Information GE provided floor anchors are designed for use ONLY on concrete floors that meet the 4-inch concrete floor requirement. Supplied floor anchors must be installed by a trained contractor, and shall be set to a minimum depth of 3-inches at each anchor point. ANY anchors having more than 1-inch of thread showing above the nut, when specified torque is set, shall have a second anchor installed in the closest adjacent hole. -

Page 70: Drilling Procedure (For Gantry And Gt1700V Table)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL • Time and Personnel • .5 hour labor on site • 2 Engineers 11.3 Drilling Procedure (For Gantry and GT1700V Table) For Lite Table drilling procedure, refer to 11.4 Drilling Procedure (For Lite Table), on page... - Page 71 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure 1-50 Drilling Position 5.) Place appropriate protection to prevent damage and dust contamination to electronic assemblies. 6.) Place the drill bushing inside each adjuster, to keep the hole vertical and centered within the adjuster.

- Page 72 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 8.) Recheck the depth of all holes by inserting an anchor backward into the hole. A ½” (13mm) or less should be showing. Re-drill if needed.

-

Page 73: Drilling Procedure (For Lite Table)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Note: If alternate location(s) are used to anchor the table or gantry, you must move the respective leveler(s) and pad(s) to the new alternate location(s) and re-drill. - Page 74 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 4.) Attach a piece of tape to the ½” concrete drill bit in order to assure a minimum of 100 mm depth of anchor hole.

-

Page 75: Gantry & Table (Gt1700V) Alternate Anchor Holes

Note: GE is not responsible for anchoring methods other than those listed in the pre-installation manual. Provided floor anchors are designed for use ONLY on concrete floors that meet the 4-inch concrete floor requirements. -

Page 76: Lite Table Redundant Anchor Holes

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 11.6 Lite Table Redundant Anchor Holes The table requires a minimum of four (4) anchors, one (1) in each corner of table base. -

Page 77: Install The Anchors (For Gantry And Gt1700V Table)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 11.7 Install the Anchors (For Gantry and GT1700V Table) For Lite Table anchor procedure, refer to 11.8 Install the Anchors (For Lite Table), on page NOTICE Each anchor must be prepared by installing a nut 13.0 mm from the top of the anchor as... - Page 78 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL ANCHOR BOLT (P/N 2106573) ANCHOR WASHER LEVELING SCREW ADJUSTER LOCK RING 33 MM [1.30” ] MAX AFTER PROPER TORQUE 24 MM [0.98” ] MIN AFTER PROPER TORQUE...

-

Page 79: Install The Anchors (For Lite Table)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Bolt centering is important to provide ± 3mm of adjustment for electrical alignment. Always use the drilling centering tool when drilling all bolt holes. -

Page 80: Alignment Recheck

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL a.) Remove the nut and washer from the anchor. b.) Add a ¼" thick washer (PN P9155BZ) under the regular anchor washer. Reassemble the anchor washer and nut and position nut so top is flush with threads of anchor. -

Page 81: Removing Table Shipping Dollies

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 11.10 Removing Table Shipping Dollies 11.10.1 Time and Personnel (FE or mechanical supplier) Required Persons Preliminary Procedure Finalization Reqs 1 Electrician 20 min. labor on-site 11.10.2... - Page 82 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure 1-62 Table Shipping Dollies Item Description Side Rails (two rails, black, one each side) Quick Release Pins (for side rails, two on each side)

-

Page 83: Section 12.0 Rear Entry Cable Box

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 12.0 Rear Entry Cable Box A rear entry cable box (B7850RC) is used when the cables to the gantry cannot be brought up inside the gantry base.The box is not supplied with the system and must be ordered separately. -

Page 84: Rear Entry With Surface Floor Duct

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 12.1 Rear Entry with Surface Floor Duct An OSHA ramp is required. The ramp must have 1’ run of slope for each 1" rise in height. -

Page 85: Section 13.0 Install Table Footswitch Assembly (Gt1700V)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 13.0 Install Table Footswitch Assembly (GT1700V) 13.1 Time and Personnel Required Persons Preliminary Procedure Finalization Reqs 1 (FE or mechanical supplier) 1.0 hour labor on-site 13.2... - Page 86 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 4.) Remove the footswitch assembly cover. 5.) Using two (2) M6 bolts, attach the footswitch assembly to the table base. Figure 1-67 Attach Footswitch 6.) Level the footswitch assembly using the three (3) level adjusters.

- Page 87 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 7.) Cut the tie-wraps from around the cables in the gantry base and route the power cables from the gantry as shown in Figure 1-69.

- Page 88 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Footswitch Ground Wire Connectors Ground Wire Ground Bar Ground Bus Connector Plate Figure 1-70 Footswitch Ground/Bus Bar 9.) Install the footswitch pedal bracket onto the installed ground bus bar.

-

Page 89: Section 14.0 Install Table Footswitch Assembly (Lite Table)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 14.0 Install Table Footswitch Assembly (Lite Table) 14.1 Time and Personnel Required Persons Preliminary Procedure Finalization Reqs 1 (FE or mechanical supplier) 1.0 hour labor on-site... - Page 90 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure 1-72 Install Front Bottom Cover Figure 1-73 Install Footswitch Pedals Page 90 Section 14.0 - Install Table Footswitch Assembly (Lite Table)

-

Page 91: Section 15.0 Remove Gantry Tilt Bracket

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 15.0 Remove Gantry Tilt Bracket 15.1 Time and Personnel Required Persons Preliminary Procedure Finalization Reqs 1 (FE or mechanical supplier) Labor on-site 15.2... -

Page 92: Section 16.0 Position The Power Distribution Unit

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 16.0 Position the Power Distribution Unit LOCKOUT/TAGOUT IS REQUIRED BEFORE PERFORMING THIS TASK. WARNING USE THE SUPPLIED LOTO KIT. ALL INSTALLATION WORK WITHIN THIS SECTION ON THE POWER &... - Page 93 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 2.) Run the main input power conductors and ground though flexible metal conduit (attached between the PDU chassis and room duct-work) so you can move the PDU away from the wall during service.

- Page 94 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure 1-77 PDU Power Connections WORK WITH THE ELECTRICAL CONTRACTOR TO BE SURE EXTERNAL WARNING POWER SOURCE IS TURNED OFF. & LOCKOUT Signed...

- Page 95 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL CONNECTION CONNECTION FROM CONNECTION TO PDU INSTALLED AND OR WALL BOX CHECKED Load - T1 TS-1 L1 Load - T2 TS-1 L2 Load - T3...

-

Page 96: Section 17.0 Install Operator Console

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 17.0 Install Operator Console 17.1 Time and Personnel Required Persons Preliminary Procedure Finalization Reqs 1 (FE or mechanical supplier) Labor on-site 17.2... -

Page 97: Section 18.0 Seismic Mounting

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 18.0 Seismic Mounting Before proceeding with seismic mounting for any of the components in this section, be sure to allow sufficient space to unbolt and move the component from its mounted location for service. -

Page 98: Power Distribution Unit

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 18.2.2 Power Distribution Unit CAUTION The PDU is very heavy and may present a crush hazard if proper precaution and tools are not used. -

Page 99: Power, Ground & Interconnect Cables

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Chapter 2 Power, Ground & Interconnect Cables NOTICE Potential for Data Loss and/or Equipment Damage To prevent potential data loss and equipment damage, please do the following: •... -

Page 100: System Component Identification

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL • Check for reasonable cable routing. Take into consideration necessary take-up distances for equipment maintenance, etc. Try to complete as neat a job as possible. - Page 101 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL PART NUMBER ABLES HORT ABLES NO. DESCRIPTION 5444556-2) 5444556) 4 PDU to Room Warning Light(s) cust. supplied cust. supplied 5 PDU to Scan Room Door Switch cust.

-

Page 102: Section 2.0 System Interconnect Diagram

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 2.0 System Interconnect Diagram Figure 2-2 System Interconnect Diagram Page 102 Section 2.0 - System Interconnect Diagram... -

Page 103: Section 3.0 Console Connections

Display Monitor 120 1.97 3050 50 5432953-4 Power Cable, Scan Monitor to NIO AC Box Scan Monitor Table 2-4 GE Healthcare Supplied NIO64 Console Cables 1.) Route the keyboard cable under the GSCB, as shown in Figure 2-3. - Page 104 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Select keyboard overlay from keyboard collector (5324605-XX) to attach. (See Figure 2- Window / Level Filming Film Film Film Print Previous Media- AutoFilm...

- Page 105 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Note: The USB cable of GSCB is reserved, please tie it with tie-wrap. Figure 2-5 GSCB and Connection ITEM DESCRIPTION GSCB - Black DB-9 (Female) Connector...

-

Page 106: Connecting The Media Tower (5270510-20/-21/-22)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Connecting the Media Tower (5270510-20/-21/-22) Front View Rear View 1) Power for Media Tower 2) Power for MOD Drive 3) DVD-RW Drive 4) External USB... -

Page 107: Connecting The Lcd Monitor

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Connecting the LCD Monitor NOTICE Equipment Damage Possible Do not touch the video signal cable connector pins as this might bend them. When connecting the video signal cable, check the alignment of the HD15 connector. -

Page 108: Connect Scan Monitor And Image Monitor For Hp Lcd

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure 2-9 Cable Routing and Keeper 3.3.2 Connect Scan Monitor and Image Monitor for HP LCD: Figure 2-10 HP E190i LCD Monitor Connections... -

Page 109: Lcd Video Monitor Setup

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Scan Monitor Video cable from Console Host PC DP to Monitor DVI Power cable from Console AC Box J10 Route through the cable keeper... -

Page 110: Host Computer Connections

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Host Computer Connections NOTICE Potential for equipment damage Never connect a mouse or keyboard with the host computer powered "ON". Doing so can destroy components within the host computer. - Page 111 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL GRN: GSCB AUDIO IN Purple Green BLUE: GSCB AUDIO OUT 1. Keyboard PINK BLUE 2. Mouse Front Side 3. Trackball USB PORTS 4. BarCode Reader AOUT 5.

-

Page 112: Switch Hub Connections

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure 2-14 Host Computer (Z840) Connections Switch Hub Connections Switch Hub located on the left bottom of the console. Plug cables into Switch Hub on console. -

Page 113: Ac Box Connections

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL AC Box Connections CAUTION The outlets are not for General Use. Operator Console outlet has a rating for 2.5A at 120VAC. Accessories should not exceed above rating. -

Page 114: Cable Arrangement

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Cable Arrangement Arrange the cables appropriately by using the cable clamps equipped on the console tables. Figure 2-17 Example: Cable Arrangement Page 114... -

Page 115: Section 4.0 Install Options

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 4.0 Install Options Note: Most shipped options can be located on the lean cart. Only large options such as the UPS and Smart Step will arrive on its own skid. -

Page 116: Customer Accessories - Head Holders And Extender

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Customer Accessories - Head Holders and Extender Open the boxes and installed the appropriate language warning labels. The head holders are shipped with shims that require installation to ensure proper fit. Check that shims are included. -

Page 117: Section 5.0 Gantry Cable Connections

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 5.0 Gantry Cable Connections Gantry Cable Connections Please refer to Figure 2-2 for complete system interconnect details. FROM CABLE DESCRIPTION Gantry Power Pan... - Page 118 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL HVAC 120V Power Pan 120V Power Input HVDC Ethernet/LAN HVAC 440V Fiber Optic Axial Drive Figure 2-18 Gantry Power Pan Connections Figure 2-19 TGPG Connections 3.) Install cables to the gantry TGPG.

- Page 119 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure 2-20 Route Cables Chapter 2 - Power, Ground & Interconnect Cables Page 119...

-

Page 120: Cardiac Monitor Setup

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Cardiac Monitor Setup Note: The following procedure is applied only if the Accessory I/F Hardware (IPC) Option is installed. 1.) Follow install instructions shipped with monitor to set up the monitor stand with basket. - Page 121 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Ground Wire Figure 2-23 Connections on Rear of Cardiac Monitor (IVY7800) 8.) Connect the power cord, ground wire, HD15 and CAT5 to the monitor panel.(See Figure 2-22).

-

Page 122: Respiratory Monitor Setup (Version 1.7)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Respiratory Monitor Setup (Version 1.7) Note: The following procedure is applied only if the Accessory I/F Hardware (IPC) Option is installed. Note: Installation of the Respiratory Monitor is done by Varian Service. -

Page 123: Section 6.0 Table Connections (Gt1700V)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 6.0 Table Connections (GT1700V) Pull and connect the cables as described in Table 2-12. The table cables are bundled with the gantry frame. Cut the cable ties to release bundles of cables. -

Page 124: Section 7.0 Table Connections (Lite Table)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 7.0 Table Connections (Lite Table) Pull and connect the following cables: CABLE DESCRIPTION 120 VAC Signal Cable Table 2-13 Cables Connected to Table... -

Page 125: Pdu Cable Connections & Configuration

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 8.0 PDU Cable Connections & Configuration CAUTION Do not work in an energized PDU. When working on the PDU, follow this simple rule: Always tag and lock out power to the PDU at the “main”... -

Page 126: Panel - 380 - 480Vac Mains "Ts1" Input Power Connection

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 8.1.1 Panel - 380 - 480VAC Mains “TS1” Input Power Connection 1.) Remove the TS3 panel front cover. 2.) Strip the wires to fit securely on the power block. -

Page 127: Hvdc Connection

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL CIRCUIT DESCRIPTION BREAKER Circuit Protection (Axial Drive) Full Winding Protection CT Gantry Service Outlets CT Gantry rotating loads Table & CT Gantry Stationary Loads Operator Console Load VMR1, Control P.S Load... -

Page 128: Connection

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 8.1.4 440V Connection Note: Refer to Table 2-3, System Interconnect Cables on page 100. Connect the internally shielded 440V cable to TS3 on the standing panel (See... -

Page 129: Pdu Control Cable

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Gantry Console Power Power Connection Connection Figure 2-33 Gantry & Console Power Connections Check box when complete. 8.1.6 PDU Control Cable The PDU control cable comes pre-terminated and should not be re-terminated in the field. Excess cable length must be stored. -

Page 130: Warning Light & Door Interlock Connections

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 8.1.8 Warning Light & Door Interlock Connections 8.1.8.1 Warning Light Configuration & Connection 1.) Warning Light is controlled by signals from the system. -

Page 131: Door Interlock Connections

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 8.1.8.2 Door Interlock Connections Door interlocks are used to prevent X-Rays from being generated when the scan room door is open. The Door Interlock circuitry in the PDU is shipped from the factory engaged. This means the system cannot generate X-ray until disengaged. -

Page 132: Section 9.0 System Ground Connections

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 9.0 System Ground Connections Gantry Base Respiratory Gating Option Gantry Power Pan Console Gantry Ground #1/0 #1/0 Table Right-side Panel Left-side Panel... -

Page 133: System Continuity & Ground Checks

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Chapter 3 System Continuity & Ground Checks NOTICE Potential for Data Loss and/or Equipment Damage To prevent potential data loss and equipment damage, please do the following: •... - Page 134 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 6.) Verify that less than 1 ohm of resistance exists between the following connections: FROM SIGNAL NAME (COLOR) PDU TS2-1 +HVDC Gantry HV Power Pan Check box when...

- Page 135 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure 3-1 Front View of NGPDU, with Covers Removed Chapter 3 - System Continuity & Ground Checks Page 135...

- Page 136 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL HVAC 120V Power Pan Figure 3-2 Gantry Power Pan WARNING TURN OFF ALL PDU CIRCUIT BREAKERS. 7.) Set an ohmmeter to the lowest scale. Check between the following points for shorts to ground.

-

Page 137: Section 2.0 Site Ground Continuity Check

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 2.0 Site Ground Continuity Check 1.) Use an ohmmeter to verify the presence of less than 1.0 ohm of resistance between each... -

Page 138: Section 3.0 Shim Installation

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 3.0 Shim Installation Time and Personnel Required Persons Preliminary Procedure Finalization Reqs 1 (FE or mechanical supplier) 10 min. 15 minutes labor on-site 5 min. -

Page 139: Procedure

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Damage to the plastic latch or the plastic screws that secure it. Figure 3-4 Correct - Head Holder is latched onto first step of plastic latch mechanism (The... -

Page 140: Finalization

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL mechanism. (The head holder does not need to be latched onto the second step) 4.) Check if the head holder has a small free-play in the horizontal direction Figure 3-7 Axial Head Holder 5.) If the rubber is too thick, repeat steps 1-4 using a thinner shim (3.5, 3.0…0.5mm) until the head... - Page 141 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL This Page Intentionally Blank. Chapter 3 - System Continuity & Ground Checks Page 141...

- Page 142 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Page 142 Section 3.0 - Shim Installation...

-

Page 143: System Covers: Installation & Alignment

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Chapter 4 System Covers: Installation & Alignment Section 1.0 Process Overview Cover install process overview: Start Install Console Covers Install Gantry Front Install PDU Cover... -

Page 144: Gantry Front Cover Installation

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Gantry Front Cover Installation Refer to Appendix A for the detailed procedure. 1.) Move the gantry to the vertical position and the front cover next to the gantry. -

Page 145: Gantry Top Covers

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Gantry Top Covers 1.4.1 Installation 1.) Take one of the top covers and align the tabs on the cover with its associated bracket. Lift and slide the cover into place. - Page 146 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure 4-4 Relocation of Spacer 4.) Attach the strap to the fastener. Figure 4-5 Strap Attachment 5.) In a similar way, install the gantry strap to the other side.

-

Page 147: Scan Windows

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Scan Windows 1.7.1 Installation Note: The front and rear covers must be installed before installing the scan window. 1.) Shape the scan window as shown in... -

Page 148: Install Gantry Base Covers

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Install Gantry Base Covers 1.8.1 Tools Required 3mm and 8mm hex wrenches 1.8.2 Procedure Assembly Sequence 1.) Position cover item 5 on gantry base with bracket slots aligned to gantry holes. Center Cover left to right and attach with (4) hardware Items 16, 2, 3 as shown and tighten. -

Page 149: Footswitch Covers Installation (Gt1700V)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 1.8.3 Footswitch Covers Installation (GT1700V) 1.) Install the footswitch cover using three (3) screws (see Figure 4-9). Figure 4-9 Footswitch Cove Installation 2.) Install cover caps on each pad. -

Page 150: Section 2.0 Install Console Covers

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 2.0 Install Console Covers Time and Personnel Required Persons Preliminary Procedure Finalization Reqs 1 (FE or mechanical supplier) 15 minutes labor on-site Tools and Test Equipment •... -

Page 151: Console Top Cover

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 4.) Tighten the four screws at the side cover. Figure 4-12 Install Side Cover Screws 2.3.2 Console Top Cover 1.) Insert two pins of top cover into the hole in the chassis. -

Page 152: Console Front Cover

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 3.) Tighten two screws at behind of top cover. Figure 4-14 Install Top Cover Screws 2.3.3 Console Front Cover 1.) Place the front cover onto console. -

Page 153: Section 3.0 Table Cover Installation (Gt1700V)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 3.) Install four screws (two screws on each side). Figure 4-16 Install Front Cover Screws Section 3.0 Table Cover Installation (GT1700V) Side Covers 1.) Remove screws (2) on tape switch. -

Page 154: Top Panel #2

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 3.2.3 Top Panel #2 1.) Install two (2) 4mm hex-head screws. Leave them loose until the bottom screws are installed. 2.) Install 6nd wire using one (1) 4mm hex-head screw. -

Page 155: Section 4.0 Table Covers Installation (Lite Table)

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 4.0 Table Covers Installation (Lite Table) Table Base Cover Figure 4-17 Table Base Cover Flapper Installation 1.) Insert two (2) plastic rings into the left side of flapper and the right side of flapper. -

Page 156: Skirt Cover Installation

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure 4-18 Installing the Table Flapper Skirt Cover installation 1.) Attach Skirt Cover to flapper brackets. 2.) Mount Skirt Cover to table bracket with two screws. -

Page 157: Bottom Cover Installation

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Bottom cover installation 1.) Install the front bottom cover using four screws. After installation, install the screw caps onto the screws. 2.) Install the foot switch pedals using four socket screws. After installation, install the screw caps onto the screws. -

Page 158: Section 5.0 Install All Option Covers

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Section 5.0 Install All Option Covers Follow the instructions that came with each of your optional components. Section 6.0 Electrical Power On & Ground Checks WARNING THIS PROCEDURE MEASURES POTENTIALLY HAZARDOUS VOLTAGES. -

Page 159: Introduction And Flowchart

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Introduction and Flowchart Start Required Line Transformer Settings Tools System Initial PDU Power-Up Configuration Emergency Stop Power Switches Check Suite Emergency Off Checks Electrical Power On &... -

Page 160: Power Switches

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL DSD3 DSD5 DSD4 Verify SW is in the normal position Figure 4-22 NGPDU Control Board 6.4.3 Power Switches Turn OFF all system power switches at their subsystems. -

Page 161: Suite Emergency Off Checks

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Suite Emergency Off Checks WARNING ONLY PERFORM THIS PROCEDURE IF YOU ARE USING PROPER PPE. 480 VOLTS MAYBE PRESENT. VERIFY ALL PERSONNEL HAVE CLEARED THE SYSTEM BEFORE YOU TURN ON WALL POWER. -

Page 162: System Power-Up

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 4.) Use a 0-750 AC voltmeter of 3/4% accuracy to measure the line-to-line voltages at L1, L2, & Verify the highest line-to-line voltage does not exceed 1.02 times the lowest voltage. - Page 163 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL PDU Power Switch Off PDU Power Switch On Gantry power pan breaker All gantry service switches Table base power Console power (Check internal breaker.) Note: (16BW45.x or later)

- Page 164 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 4.) Press the alignment light push button. 5.) Verify that the gantry did not rotate. ROTATION SAFETY CHECKLIST 1.) Manually rotate the gantry 360 degrees.

-

Page 165: Install Pdu Covers

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Install PDU Covers 6.8.1 Time and Personnel Required Persons Preliminary Procedure Finalization Reqs 1 (FE or mechanical supplier) 10 minutes labor on-site 6.8.2 Tools and Test Equipment •... - Page 166 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Reset Button Figure 4-25 Reset buttons on Gantry Switch Note: Emergency Stop buttons are located on the front of the gantry (2 in all), as noted in Figure 4-26.

-

Page 167: Section 7.0 Mechanical Installation Completion Checklist

All customer items placed on a cabinet or on a counter and labeled customer material. All system service tools placed in the GE service cabinet. System software and options left on the lean cart in the software tray ... - Page 168 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL This Page Intentionally Blank. Page 168 Section 7.0 - Mechanical Installation Completion Checklist...

-

Page 169: Gantry Cover Removal And Dolly Setup

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Appendix A Gantry Cover Removal and Dolly Setup Section 1.0 Gantry Cover Removal NOTICE Follow ALL required safety and PPE procedures customary for your organization, when working on this product. -

Page 170: Side Cover Removal

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Opening in Gantry Covers Scan Window SCAN WINDOW IN POSITION REMOVE SCAN WINDOW Figure A-1 Scan Window Removal 1.3.2 Side Cover Removal 1.) If removing side cover in preparation for front cover removal, move the table to its lowest position before powering off gantry. -

Page 171: Top Cover Removal

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Switch Panel (SSP) as applicable for the service being performed. See Figure A-4. Figure A-4 Service Switch Panel 5.) Repeat Steps 1and 2 for the left side cover. -

Page 172: Gantry Front Cover

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 3.) Unscrew two screws that secure the top cover with Philip top screwdriver. Top cover Screws Figure A-6 Screws Securing Top Cover 4.) Take the end of the top cover nearest to the side cover and tilt upwards. - Page 173 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL IN PERSONAL INJURY OR DAMAGE TO COVERS OR OTHER FACILITY ITEMS. ONLY USE DOLLIES ON FLAT SURFACES.. CAUTION Rotating arms on the stand are supposed to be stiff. If they fall freely, tighten the tensioning nuts.

- Page 174 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL FAILURE TO DO SO WILL RESULT IN INSTABILITY DURING FRONT COVER HANDLING. 5.) Insert top post into the base riser post. Align the key for complete engagement.

- Page 175 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 5.) Assemble the front cover dolly. a.) Tighten the two (2) shoulder bolts to the gantry securely. This makes cover installation easier (see Figure A-12).

- Page 176 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 7.) Remove the Mylar (scan) window. 8.) Remove front cover. a.) Disengage upper cantrell bracket on right side of the cover. Figure A-14 Releasing Cover Brackets A.) Disengage the locking mechanism on the upper cantrell brackets by using your...

- Page 177 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL b.) Disengage the left side of the front cover. A.) Remove the small cover from the front cover. B.) Loosen M12 screw. Figure A-16 Disengage the Left Side of the Front Cover 9.) Rotate front cover away from gantry.

- Page 178 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure A-18 Front Cover Removal Sequence 10.) Rotate the cover horizontally and move it back and over the table to a safe location. Once in a safe location, you may over-rotate the cover full vertically but upside down.

- Page 179 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL remove the Display (see Figure A-19). Figure A-19 Gantry Display Removal b.) Loosen two lock screws of the rear cover. Figure A-20 Lock Screws of the Rear Cover Appendix A –...

- Page 180 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Side the rear cover backward. Figure A-21 Rear Cover Slide d.) Loosen the lock screw of the right top fan of the gantry, and rotate the right top fan.

- Page 181 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL e.) Place the Display in the bracket on the right side of the gantry. (see Figure A-23) Figure A-23 Gantry Display Service Mounting Location 12.) Remove right gantry control assemblies, and place it into its service position.

- Page 182 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Align the ball studs with their associated receivers and snap into place. Figure A-25 Control Panel Service Position d.) Connect FCVR BKHD J1 cable to terminator located on the cantrell arm. See...

-

Page 183: Bore Cover Removal

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL end of the connectors to display and control panel. Figure A-27 FRT CVR J3 Cable 1.3.5 Bore Cover Removal 1.) Remove gantry side covers, top covers and Mylar window. Refer to each cover’s removal procedure. - Page 184 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Figure A-28 Breath Navigator I/F Cable 4.) Remove the 2 screws located at two bottom brackets of the bore cover. Then loosen the screw on top.

- Page 185 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 5.) Pull up safety pin small knob on the bore cover top bracket and rotate 1/4 turn to keep the safety pin disengaged.

-

Page 186: Gantry Rear Cover

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 1.3.6 Gantry Rear Cover Sliding Out Rear Cover DANGER ELECTROCUTION HAZARD. HIGH VOLTAGE PRESENT. POTENTIAL FOR INJURY IF COVERS REMOVED AND POWER IS LEFT "ON". - Page 187 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Rear Cover Removal CAUTION Pinch Hazard Uncontrolled cover movement Make sure the wing nuts are tightened on the cover dollies prior to releasing cover from gantry mounts.

- Page 188 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL This Page Intentionally Blank. Page 188 Section 1.0 - Gantry Cover Removal...

-

Page 189: Pictorial Representation Of Required Tools

” X ” (included with 9-34496) Dental Pick Diagonal Cutting Sears Industrial: Small (9-45077) Pliers * Part Numbers given for reference only. GE Healthcare does not endorse any tool brand name. Appendix B - Pictorial Representation of Required Tools Page 189... - Page 190 Sears Industrial: ¼” (9-SK45508) Hex Key (Allen Sears Industrial: U.S. Standard (9-46284) Wrench) Set * Part Numbers given for reference only. GE Healthcare does not endorse any tool brand name. Page 190 Appendix B - Pictorial Representation of Required Tools...

- Page 191 Screwdriver Set Sears Industrial: Phillips & Straight (9-41505) Socket Set Sears Industrial: Standard " (9-34496) * Part Numbers given for reference only. GE Healthcare does not endorse any tool brand name. Appendix B - Pictorial Representation of Required Tools Page 191...

- Page 192 " (9-WR3470) Universal Joint Sears Industrial: " (9-4435) Vacuum Cleaner Sears Industrial: 8 Gal (9-17780) * Part Numbers given for reference only. GE Healthcare does not endorse any tool brand name. Page 192 Appendix B - Pictorial Representation of Required Tools...

-

Page 193: Operating Table Installation And Adjustment

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Appendix C Operating Table Installation and Adjustment Section 1.0 Smart Workspace Table Assembly and Adjustment This section describe the Smart Workspace table assembly and adjustment procedure 1.) Remove all the transportation packaging from the Smart Workspace Table, use the packing... - Page 194 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 3.) Prepare crossbar and two beams. Beam (x2) Upper Crossbar Figure C-2 Cross and Beams 4.) Install the upper crossbar by screwing seven screws, three screws for tabletop, four screws for left and right legs.

- Page 195 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 5.) Install two beams to the left and right legs as shown in Figure C-4. Note to keep all screws loose. Left leg...

- Page 196 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 8.) Stick EVA A on the teams and EVA B on the right leg as shown in Figure C-6. EVA B EVA A Figure C-6 EVA Attaching 9.) Overturn the table, then place monitors and route cables to the table.

-

Page 197: Remote Monitor Option Console Wiring

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL Appendix D Remote Monitor Option Console Wiring Section 1.0 Remote Monitor Wiring Overview Figure D-1 Remote Monitor Wiring Section 2.0 Wiring Installation Power Down System... -

Page 198: Install 4-Way Splitter

GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL USE PROPER LOCKOUT/TAGOUT PROCEDURES AT THE “MAIN” DISCONNECT BEFORE WORKING ON EQUIPMENT. CAUTION Do not apply power to the system until all work has been completed and all covers are in their proper place. - Page 199 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 1.) Install the splitter: a.) Remove Four rubber legs from the splitter. Figure D-3 Removing Four Rubber Legs b.) Remove the splitter base plate from the console.

- Page 200 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL c.) Install the base plate to the splitter with the flat head screws. Screws Splitter Base Plate Figure D-5 Installing Base Plate d.) Install the splitter with the base plate to the console.

- Page 201 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL 2.) With the monitor and computer switched off, remove the video cable from the back of the image monitor. See Figure D-7. (The monitor shown below may appear different from the one you have.) Remove this cable from the HP computer video connector.

- Page 202 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL d.) Add BNC terminators to unused outputs. Figure D-8 Splitter connections 7.) Set the Video Gain Level to 1.0 and the Sync Level to HI.

- Page 203 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL AC Box (5412524-2) 120VAC ETL Label Rating Plate WEEE Label EMC Label Figure D-10 AC Box Grounds Appendix D - Remote Monitor Option Console Wiring...

- Page 204 GE C OMPANY 5472001-1EN, R CT680 S CT670 I IRECTION EVISION PTIMA ERIES AND PTIMA NSTALLATION ANUAL This Page Intentionally Blank. Page 204 Appendix D - Remote Monitor Option Console Wiring...

- Page 206 www.gehealthcare.com...