Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Eagle 1000A

- Page 1 Operations Manual Eagle 1000 Series Stretch Wrapper Models A & B - 1 -...

- Page 2 READ ALL INSTRUCTIONS CONTAINED IN THIS MANUAL PRIOR TO MACHINE INSTALLATION! - 2 -...

-

Page 3: Table Of Contents

Contents page Machine Safety Information Safety & Warnings Specifications Outline & Applications Position of Operation Safety Precautions Prior to Operation Machine Installation Machine Structure & Main Components Transportation Installation Operational Environment Operation Operational Steps & Film Loading Basic Machine Operation Maintenance &... -

Page 4: Safety & Warnings

1.1 Safety & Warnings ▪ Before servicing, always power down and unplug the machine from the power source. ▪ Ensure that the correct voltage is being supplied from the power source. ▪ Do not touch the turn table while machine is in operation. ▪... - Page 5 (Turntable may move) 1.1 Safety & Warnings DO NOT MODIFY OR REMOVE WARNING LABELS Film Carriage Do Not Open While Running Control Panel (Bottom) Electrical Hazard Do not service machine while powered up and connected to power source! - 5 -...

-

Page 6: Specifications

1.2 Specifications - Eagle 1000A Power Supply 110VAC, 60Hz Turntable Speed 0-10 RPM Turntable Diameter 59” Turntable Diagonal 80” Turntable Height 3.125” Pre-Stretch Motor Pre-Stretch Gear Ratio Pre-Stretch Chain Film Stretch Manually Adjustable on Carriage Max Film Height 87” Mast Height 94”... - Page 7 1.2 Specifications - Eagle 1000B Power Supply 110VAC, 60Hz Turntable Speed 0-10 RPM Turntable Diameter 59” Turntable Diagonal 80” Turntable Height 3.125” Pre-Stretch Motor 1/3 HP 1390 RPM 220V 1:20 Gearbox Pre-Stretch Gear Ratio 1:12 Pre-Stretch Chain 06B-1 ISO Film Stretch...

-

Page 8: Position Of Operation

1.3 Outline and Application Field This machine features a PLC controller. The electric subassembly uses world famous products such as OMRON, LG and TE components. This provides a reasonable, high reliability and convenient use for the machine. It can advance production efficiency and prevent goods from being damaged during transportation. - Page 9 ▪ DO NOT push, drag, or slide machine! Doing so will cause severe damage! - 9 -...

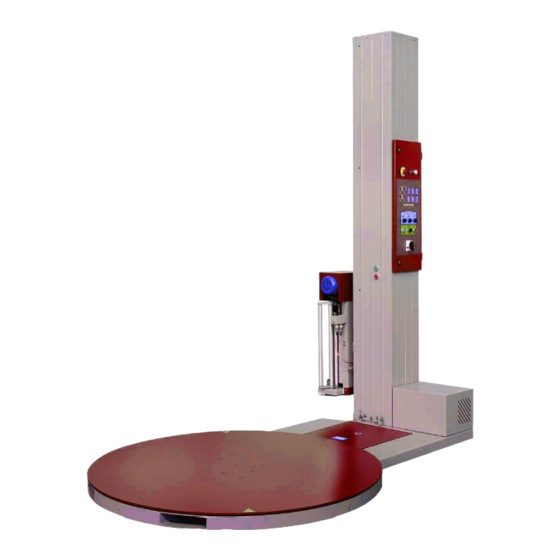

- Page 10 2.1 Machine Structure & Components Illustration Fig. 2-1 Control Panel Film Carriage Mast Turntable - 10 -...

-

Page 11: Transportation

2.2 Transportation You must have at least 4ft fork tubes or tube extensions fully inserted into the machine and a forklift rated for 3,000lbs to transport the machine safely. Do not raise the load more than 6” off of the ground. -

Page 12: Installation

2.3 Installation Step 1 - Place the machine in the desired location using a tow motor or crane capable of handling a load of 3,000lbs. (See Fig. 2-3) Fig. 2-3 Fig. 2-4a Fig. 2-4b Step 2 – While lifting the mast, use caution to ensure that wires and connectors are not pinched. (See Fig. - Page 13 Fig. 2-5 (See Fig. 2-5) Step 4a (Eagle 1000B) - Affix the carriage onto the corresponding position on the mast and fasten with four M8 bolts. Insert the connector plugs on the front of the carriage into the receptacles. Do not force the connectors together.

- Page 14 2.3 Installation Step 4b (Eagle 1000A) - Insert the connector plug inside the bottom of the mast into the corresponding receptacles. (See Fig 2-7) M8 Screw Sensor Wire Socket Manual Stretch Roller Transition Roller Fig. 2-7 Step 5 - Verify that all screws are tight and then turn on the power. Verify power indicator is on.

-

Page 15: Operational Environment

2.4 Operational Environment • Machine should be far from smoke, preferably in a dry, well-ventilated area. • Normal environment temperature should be within 32ºF and 104ºF. • No special requirements for electromagnetic radiation. • Machine should not be placed under direct lighting as it may cause photoelectric eye to malfunction. -

Page 16: Operational Steps & Film Loading

BEFORE LOADING FILM, PRESS THE EMERGENCY STOP BUTTON AND TURN THE POWER SWITCH TO THE OFF POSITION Loading stretch film into pre-stretch carriage (Eagle 1000B) Step 1 - Loosen fastening screw "A" and take off roll holder "B". (See Fig. 3-1) - Page 17 Note: Do not slam or force the carriage door closed. Doing so may cause damage to hinges and carriage door locking mechanism. Do not use sharp objects on or near rollers as they can be easily damaged. - 17 -...

- Page 18 BEFORE LOADING FILM, PRESS THE EMERGENCY STOP BUTTON AND TURN THE POWER SWITCH TO THE OFF POSITION Loading stretch film into non pre-stretch carriage (Eagle 1000A) Step 1 - Loosen fastening screw "A" and take off roll holder "B". (See Fig. 3-4)

-

Page 19: Basic Machine Operation

3.2 Basic Machine Operation 1. Counts/Timer Value Display 6. Start Button 2. Machine Functions 7. Automatic / Manual 3. Turntable Speed Mode Switch 4. Carriage Speed 8 Machine Stop Button 5. Film Tension (if applicable) 9. Power Switch The turntable speed and load force knobs can be adjusted to achieve desired film tension. The speed and load force work in conjunction. - Page 20 3.2 Basic Machine Operation Step 1 – Turn on the power to the machine. Step 2 – Using the Auto/Hand switch, select a job mode. Step 3 – Place the load to be wrapped onto the turntable. Step 4 – Connect the loose end of the stretch film to the bottom of the load (ie: corner of the pallet) Step 5 –...

-

Page 21: Carriage Load Safety Switch

4.1 Carriage Load Safety Switch (Eagle 1000B) USE EXTREME CAUTION WHEN ADJUSTING CARRIAGE SWITCH AS IT CAN BE DAMAGED BY OVER ADJUSTMENT Step 1 - Open Carriage Door Step 2 - Unload any and all stretch film from machine Step 3 - Loosen jam nut... -

Page 22: Turntable Home Switch

4.2 Turntable Home Switch BE SURE TO DISCONNECT ALL POWER TO THE MACHINE PRIOR TO ANY MAINTENANCE WORK Fig. 4-1 Fig. 4-2 Turntable ▪ Remove the six M10 flat head cap screws in the turn table. ▪ Screw in one M10 eyebolt rated for lifting into the tapped hole in the turn plate. Lift the turn table using a hoist and chain rated for a 500lb load. - Page 23 4.3 Turntable Idler Wheels Fig. 4-4 ▪ Remove all 24 idler wheels supporting the turntable rotation if there is excessive bearing play. If the diameter is less than 53mm or there is abnormal noise during operation, replace the bad contact rollers. (See Fig.

-

Page 24: Turntable & Carriage Adjustment

4.4 Turntable & Carriage Adjustment Test Operation Turntable ▪ Turn on the power ▪ Verify there is no play in the turntable and that the fasteners are tight. ▪ The chain tension controls the amount of play in the turntable. The chain should have no more than ±0.25"... - Page 25 ▪ Look and listen for smooth and consistent operation. If the action is not smooth, check the carriage chain for obstructions, wear, or damage. - 25 -...

-

Page 26: Replacement Parts

Components to be replaced by the operator. Name Part Number Positioning plate FG-135A String ring FG-138A Micro switch (Eagle 1000B) Tension spring (Eagle 1000B) 01-162 Belt (Eagle 1000A) M-L105 Idler wheel FG-013A Components that must be replaced by a professional. -

Page 27: Base (Turntable)

5.1 Illustration Base - 27 -... - Page 28 5.1 Illustration Base (continued) Name Part Number Turntable FG-023 Pedestal FG-7000AG Roller Wheel Assembly (1) Roller Wheel Assembly (2) Large Chain Wheel FG-008 Bearing 51213 Bearing 6009 Travel Switch Module (1) FG-009 Count Travel Switch TZ-918 Tension Chain Wheel FG-021 Tension Wheel Seat FG-011 Chain...

-

Page 29: Roller Wheel Assembly

5.2 Illustration Roller Wheel Assembly (1) Name Part Number Roller Wheel Body FG-013A Bearing 6202 Roller Wheel Bearing FG-014A Spacer Ring FG-015A L=23 - 29 -... - Page 30 5.3 Illustration Roller Wheel Assembly (2) Name Part Number Roller Wheel Body FG-013A Bearing 6202 Roller Wheel Bearing FG-014A Spacer Ring FG-015A L=16 Spacer Ring FG-015A L=9.5 - 30 -...

-

Page 31: Mast

5.4 Illustration Mast - 31 -... - Page 32 5.4 Illustration Mast (continued) Name Part Number Mast Cover Plate FG-389B Mast Cover Braket FG-388B Reduction Gear Bearing Base FG-398B Carriage Motor YS6334/B14 Reducer NMRV040/60- Motor Shaft FG-390B Drive Sprocket FG-060 Carriage Bolts Chain Slide Way FG-393B Support Iron Box FG-392B Sliding Block Sliding Block Base...

- Page 33 - 33 -...

-

Page 34: Pre-Stretch Carriage

5.5 Illustration Pre-Stretch Carriage - 34 -... - Page 35 5.5 Illustration Carriage – Continued from previous page. Name Part Number Motor Cover FG-123 Pre-Stretch Motor NMRV040/20- YS6334-B14 Pre-Stretch Motor Base Plate FG-111C Bearing Block FG-132 Pre-Stretch Roller FG-114 Straining Ring FG-138A Tightening Screw Film Positioning Plate FG-135A Film Bearing FG-134 Micro Switch Frame 1060.180.1.PL...

-

Page 36: Non Pre-Stretch Carriage

Swing Shaft (short) FG-142 Micro Switch MQS-216 5.6 Illustration Non Pre-Stretch Carriage - 36 -... - Page 37 5.6 Illustration Carriage – Continued from previous page. Name Part Number Hand Shank FG-164A Eccentric Gear FG-163 Indicator Block FG-167 Tension Block FG-161 Tensioning Block Shaft FG-162 Adjustment Shank FG-158 Bracket FG-159 Tightening Screw Retaining Ring FG-138A Film Locating Plate FG-135A Film Shaft FG-134...

- Page 38 Asperities Belt 40×δ2×3300mm - 38 -...

-

Page 39: Electrical Schematics

6. Electrical Schematics - 39 -... - Page 40 6. Electrical Schematics - 40 -...

- Page 41 6. Electrical Schematics - 41 -...

- Page 42 6. Electrical Schematics - 42 -...

- Page 43 7. Control Panel LEDs - 43 -...