Chapters

Table of Contents

Summary of Contents for Toshiba W-705

- Page 1 FILE NO. 110-200006 SERVICE MANUAL NC MECHANICAL DECK VIDEO CASSETTE RECORDER W-705 General Descriptions General Descriptions Adjustment Procedures Adjustment Procedures Servicing Diagrams Servicing diagrams Parts List Part List Mar., 2000 Y...

- Page 2 SAFETY NOTICE SAFETY PRECAUTIONS LEAKAGE CURRENT CHECK Plug the AC line cord directly into a 120V AC outlet (do Measure the AC voltage across the 1500 W resistor. not use an isolation transformer for this check). Use an The test must be conducted with the AC switch on and AC Voltmeter, having 5000 W per volt or more sensitiv- then repeated with the AC switch off.

- Page 3 Adjustment Procedures Servicing Diagrams Adjustment Procedures Servicing Diagrams Parts List Parts List SECTION 1 GENERAL DESCRIPTIONS 1. OWNER'S MANUAL...

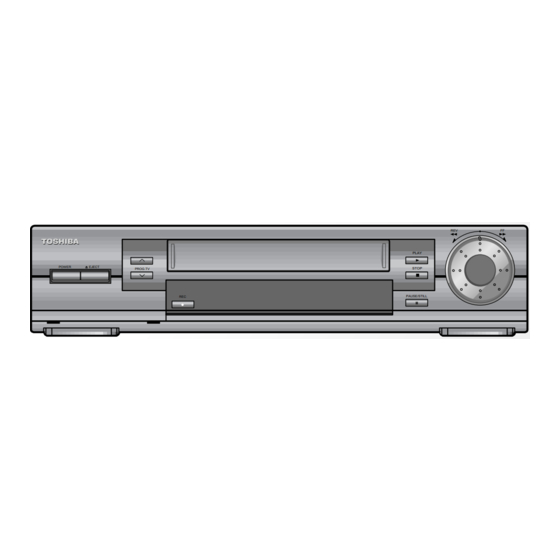

- Page 4 Video Cassette Recorder W-705 OWNER’S MANUAL PLAY POWER EJECT PROG.TV STOP PAUSE/STILL This publication is printed on recycled paper 70971839...

-

Page 5: Safety Precautions

Address: 1420 Toshiba Drive, Lebanon, TN37087 Telephone: 615-449-2360 User Installer Caution: Changes or modification made to this equipment not expressly approved by Toshiba Corporation or parties authorized by Toshiba Corporation could void the user’s authority to operate the equipment. Note to CATV system installer: This reminder is provided to call the CATV system installer’s attention to Article 820-40 of the... -

Page 6: Important Precautions

It is permissible to record television programs, film, video tapes and other material only in the event that third party copyrights and other rights are not violated. ® As an E Partner, TOSHIBA has determined that this product or NERGY ® product model meets the E guidelines for energy efficiency. -

Page 7: Important Safety Instructions

IMPORTANT SAFETY INSTRUCTIONS CAUTION: PLEASE READ AND OBSERVE ALL WARNINGS AND INSTRUCTIONS GIVEN IN THIS OWNER’S MANUAL AND THOSE MARKED ON THE UNIT. RETAIN THIS BOOKLET FOR FUTURE REFERENCE. This set has been designed and manufactured to assure personal safety. Improper use can result in electric shock or fire hazard. - Page 8 6. Water and Moisture Do not use this product near water - for example, near a bath tub, wash bowl, kitchen sink, or laundry tub; in a wet basement; or near a swimming pool and the like. 7. Cleaning Unplug this product from the wall outlet before cleaning. Do not use liquid cleaners or aerosol cleaners.

- Page 9 IMPORTANT SAFETY INSTRUCTIONS 12. Lightning For added protection for this product during storm, or when it is left unattended and unused for long periods of time, unplug it from the wall outlet and disconnect the antenna or cable system. This will prevent damage to the product due to lightning and power-line surges.

-

Page 10: Table Of Contents

Contents INTRODUCTION Variable Speed Playback ....22 • Picture Search Provides important notes and general explanation of the VCR, including names of the • Still Picture buttons, jacks, etc. • Slow-motion Picture • Frame Advance SAFETY PRECAUTIONS ....2 • Double Speed Playback IMPORTANT PRECAUTIONS .... -

Page 11: Identification Of Controls

INTRODUCTION Identification of Controls See the page in for details. This manual shows the names of buttons in italics. Front Panel CHANNEL EJECT PLAY Cassette compartment POWER STOP PLAY SHUTTLE POWER c EJECT CHANNEL STOP LINE IN 2 PAUSE/STILL LINE IN 2 VIDEO L-MONO-AUDIO-R VIDEO jack... -

Page 12: Vcr Display

VCR Display VCR indicator Timer recording indicator Cassette indicator REMAIN indicator OFF indicator POWER indicator AM PM POWER REMAIN Hi-Fi (L/R) indicators L: Left channel R:Right channel TIMER off: Normal track Multifunctional indicator REC (Recording) DT (Digital Auto Tracking) indicator indicator Channel indicator Tape speed indicator... -

Page 13: Preparation

PREPARATION How to Use the Remote Control This section explains how to get ready for remote control operation. Setting up the Remote Control Open the battery compartment lid on the rear panel. Install 2 batteries (“AAA” size) following the polarity diagrams. Close the battery compartment lid. -

Page 14: Connections

PREPARATION Connections Before you use this VCR, it is necessary to connect it to your TV. Several ways of connecting are available depending on your use of TV or cable box. Select one which is applicable to your equipment. Antenna/VCR/TV Connection Disconnect the antenna cable from your TV and connect it to the RF IN terminal on the VCR. - Page 15 Connections (continued) Cable Connection Choose one of the below according to your usage of the cable box. This set-up will enable you to: – record an unscrambled channel. – watch an unscrambled channel while recording – record an unscrambled channel while watching another (only when you connect a cable- compatible TV).

- Page 16 This set-up will enable you to: – watch an unscrambled or scrambled channel while recording it. – record any channels through the cable box. Cable Box You will need to: • set TV channel 3 or 4 to receive video signals. (See page 11.) •...

-

Page 17: Auto Set Up

PREPARATION Auto Set Up The Auto Set Up function automatically sets the tuner channels and clock when power is first connected to the VCR. Preparation • Turn on the TV, and select the video channel (3 or 4), or the video input mode if you made the Audio/Video connection (page 11). -

Page 18: Initial Settings Using On-Screen Display

PREPARATION Initial Settings Using On-screen Display Language selection must be set first when the VCR is first plugged in, or after it encounters a power failure. You can also easily make necessary settings using the on-screen displays. Preparation • Turn on the TV, and select the video channel (3 or 4), or the video input mode if you made the Audio/Video connection (page 11). -

Page 19: Setting The Clock

Initial Settings Using On-Screen Display (continued) Setting the Clock Press ENTER to start the “AUTO” clock set feature. Example: To set the clock to 2:30 p.m. on After a while, the VCR automatically updates August 25 (summer time) 2000. the clock using the data broadcast by the local TV stations. -

Page 20: Storing Channels On The Vcr

PREPARATION Storing Channels on the VCR This section is required if you receive only normal TV or unscrambled cable channels, or use a cable box between your TV and the VCR. Incoming Antenna/Cable (CATV) Signals The VCR scans through all receivable TV and CATV channels and stores only the active ones in your area into the memory. - Page 21 Storing Channels on the VCR (continued) Adding or erasing channels Cable Box/DSS Output Channel Setting Adding channels To set the Cable Box/DSS output Channel on the If a desired channel cannot be scanned VCR. automatically because of a weak signal, it can be added to the memory.

- Page 22 Channel reference chart Number on the VCR – Corresponding channel number 1(A-8) 4 5(A-7) 6(A-6) CATV STD (HRC/IRC) BB CC DD EE FF GG HH LL MM NN OO … … – – … PP QQ RR SS UU VV WW XX ZZ AAA BBB 65 …...

-

Page 23: Video Cassette Use

PREPARATION Video Cassette Use Video Cassette Use Loading a cassette Push the cassette into the cassette compartment with the window side facing up and the label side towards the front. The VCR is automatically turned on. The indicator will appear in the VCR display. Ejecting a cassette Press EJECT . -

Page 24: Playback

PLAYBACK Playback This section explains the basic playback operation. Preparation • Select the video channel (3 or 4) or video input mode on the TV. • Press VCR to set the remote control operating the VCR. Basic Playback Load a recorded cassette. POWER Power is turned on. -

Page 25: Variable Speed Playback

PLAYBACK Variable Speed Playback You can play back a tape at various tape speeds. Picture Search A tape runs at 5 times or 7 times the normal playback speed so that you can quickly locate a particular scene. Press FF or REW during playback. TV/VCR The tape runs at 5 times the normal playback speed. -

Page 26: Frame Advance

Frame Advance Double Speed Playback A picture advances frame by frame. A tape runs at twice the normal speed. Press PLAY during still playback. Press PLAY during playback. Each time you press PLAY , the picture The picture runs at twice the normal playback advances one frame. -

Page 27: Operation

PLAYBACK Useful Functions in Tape Operation These functions will help your playback. S-VHS Quasi Playback (SQPB) • This VCR can also play back a tape which is recorded in S-VHS format. But the playback picture does not have the same quality and resolution as the original S-VHS playback picture. -

Page 28: Index Search Function

Press PROG to exit. Press REMAIN/COUNTER . The remaining time (“RT - : - -”) appears in the VCR display. Notes • The displayed remaining time is an approximation. • The remaining time is calculated according to the tape speed (SP or SLP) and the cassette type. -

Page 29: Recording

RECORDING Recording a TV Program This section explains the basic recording operation. Preparation Select the video channel (3 or 4) or video input mode on the TV. Basic Recording Load a cassette with the safety tab attached. INPUT Press TV/VCR so that the “VCR” SELECT POWER indicator appears in the VCR display. -

Page 30: Timer Program Recording

RECORDING Timer Program Recording The programmable timer allows you to record up to 6 different programs over one month. Preparation • Select the video channel (3 or 4) or video input mode on the TV. • Make sure that the clock is set correctly (page 16). •... - Page 31 Timer Program Recording (continued) Move to the next using CURSOR SET UP PRESET PROGRAM RIGHT , and set the hour and CH DATE 25 8 / 30 : 30 – : –– minutes of the recording start time. –– – / –– – : –– –...

- Page 32 Confirming the timer programs If a power failure occurs during the (in the timer standby mode) timer program recording (including VCR Plus+ ® system recording (page Press PROG . 32)) The screen for confirming will appear. • When a power failure has occurred, “- -:- -” appears in the VCR display.

-

Page 33: Vcr Plus+ System Set-Up

RECORDING ® VCR Plus+ system Set-up ® VCR Plus+ system is a timer recording system for an easier programming that requires you only to enter ® a PlusCode programming number assigned to a desired program. This section explains the necessary set-up to make VCR Plus+ ®... - Page 34 Preparation • Select the video channel (3 or 4) or video input mode on the TV. • Prepare the list like below. Example Guide channel number Your home channel number (on the channel line-up Station chart supplied by cable companies) (on the TV Guide, local TV listings etc.) ESPN Guide Channel Setting...

-

Page 35: Vcr Plus+ System Recording

RECORDING ® VCR Plus+ system Recording ® After performing the VCR Plus+ system set-up, you can easily program a recording simply by entering ® the PlusCode programming number. The numbers are published in the TV listings of newspapers, TV guide magazine, etc. Preparation •... - Page 36 Press ENTER . PROGRAM SET UP PRESET The program setting is now memorized. CH DATE 25 8 / 30 9 : 30 10 : 00 –– – / –– – : –– – : –– – –– – / –– – : –– –...

-

Page 37: Mts Broadcast Compatibility

RECORDING MTS Broadcast Compatibility This VCR can receive or record MTS (Multichannel TV Sound) broadcasts. By connecting the VCR to your stereo system or stereo TV, you will experience the SAP or stereo sound. Preparation Connect a stereo TV or stereo system to the AUDIO OUT jacks of the VCR. Recording the SAP/Stereo Broadcast On the SET UP screen (page 15), PROGRAM... -

Page 38: Simulcast Recording

RECORDING Simulcast Recording When TV program such as MTV, HBO or MAX is being simulcast in FM stereo in your area, the VCR can also record the simulcast sound from an FM stereo tuner or receiver onto the Hi-Fi track and normal track. -

Page 39: Additional Information

Multi Brand Remote Control The remote control can be compatible with various brands of TV by setting their control codes. The TOSHIBA code has initially been set to control TOSHIBA TVs. Setting Control Codes Press TV to set the remote control operating your TV. - Page 40 Table of Brand Codes Brand name of your TV Brand name of your TV Brand Code Brand Code Toshiba Proton Bell & Howell Pulser Carver Quasar 07, 15 Celebrity Radio Shack Citizen Curtis Mathes 09, 12 Realistic 09, 11, 13...

-

Page 41: Before Calling Service Personnel

ADDITIONAL INFORMATION Before Calling Service Personnel Check the following symptoms before requesting servicing. No power. The desired sound is not heard, such as SAP, stereo, or regular sound. • The power cord is not plugged in. • Setting of sounds is not correct. –... - Page 42 The remote control does not work properly. • The batteries are exhausted. – Replace all batteries. (page 10) • The remote control is operated beyond the operating range. – Make sure the remote control is within 30° of the remote sensor on the VCR. (page 10) •...

-

Page 43: Specifications

Specifications Power supply: 120 V AC, 60 Hz Power consumption: 19 W 430 × 96.5 × 281 mm (W.H.D.) External dimensions: Mass: 3.8 kg Channels received: VHF: Channels 2–13 UHF: Channels 14–69 CATV: Channels 1–125 UHF/VHF: 75 Ω F type connector Antenna input/output terminals: Signal system: Standard NTSC... -

Page 44: Limited Warranty

LIMITED WARRANTY TOSHIBA VIDEO CASSETTE RECORDER Toshiba America Consumer Products, Inc. (“TACP”) and Toshiba Hawaii Inc. (“THI”) make the following limited warranties. These limited warranties extend to the original consumer purchaser or any person receiving this set as a gift from the original consumer purchaser and to no other purchaser or transferee. - Page 45 Canadian consumers are requested to complete the special Canadian “Warranty Registration Form” enclosed and forward this completed form with a copy of bill of sale to TOSHIBA OF CANADA to “Register and Validate” their warranty. Product must be purchased from an Authorized Canadian Dealer.

- Page 46 General Descriptions Servicing Diagrams Parts List General Descriptios Servicing Diagarms Part List SECTION 2 ADJUSTMENT PROCEDURES 1. MECHANICAL ADJUSTMENT 1-1. Mechanical Parts Location 1-2. Servicing Jig List 1-3. Main Parts Servicing Time 1-4. Mechanism Check Method 1-5. Mechanical Deck Removing and Mounting Method 1-6.

- Page 47 1. MECHANICAL ADJUSTMENT 1-1. Mechanical Parts Location Head cleaner ACE head Slip ring assembly No.8 guide cap Pinch roller Impedance roller Cylinder assembly FE head Loading motor T slider S slider No.9 guide lever Tension lever FL cam gear S brake T brake Band brake T reel table...

- Page 48 Capstan motor Worm gear T loading lever holder assembly Worm wheel T loading lever assembly Reel belt Loading drive gear Joint gear 1 Tension drive Joint gear 2 lever Cam slider Up/down lever S-VHS switch Holder clutch assembly Pinch drive lever Fig.

- Page 49 1-3. Main Parts Servicing Time 1. Part replacement time differs from servicing life time of each part. 2. Following table is prepared based on a standard condition (room temperature, room humidity). The replacement time will be varied depending upon operation environment, using methods, operation duty. 3.

- Page 50 1-4. Mechanism Check Method Does the loading motor and the If the abnormal condition is caused by the mechanism Loading motor is worm wheel rotate without abnormal. a cassette after turning itself, analyze the cause according to the following the power ON? procedures.

- Page 51 1-4-4. Check by Defective Analyzing Table Note: If the abnormality causes the mechanism abnormal • After replacing the defective parts according to the condition, presume, confirm and treat the defective procedure of the treatment method for the damage according to the defective analyzing table. and phase mismatch of mechanical part, check the operation of the mechanism again, since the same (or (1) Manual Mechanism Operation (Mode Shift) Method...

- Page 52 Table 1-4-2 Defective analyzing table Case Defective phenomenon (Main items) Presumed cause (Main cause) Check method Power does not turn on. Loading <General> (1) Check the mode shift "Cas- operation is defective. sette out « FF/REW position" (1) Mechanism stops due to mechanical phase can be performed when turning Mode shift operation is defective.

- Page 53 1-4-5. Unloading Method of Cassette in Manual 1-4-6. Check Method of Each Operation Mode without Loading the Cassette The mechanical deck can not be removed at the condition the cassette is loaded, since one of screws for 1. Put some tapes on both left and right sides of the mounting the mechanism deck with the chassis is cassette holder so that the start/end sensors are not located under the cassette.

- Page 54 1-5. Mechanical Deck Removing and Mounting Method 1-5-1. Cabinet Removal 1-5-2. Mechanical Deck Removal 1. Unplug the power supply plug (1) from the outlet. 1. Remove the cabinet. (Refer to section 1-5-1, Cabinet 2. Remove the three screws (3) securing the Top cover Removal.) (2).

- Page 55 6. Remove the power supply cord holder (4) from the chassis. 7. Remove the two screws (5) to detach the rear panel(6). 8. Remove the screw (7) to detach the main PC board (8). Power supply Screw (7) cord holder (4) Main PC board (8) Screw (5) Screw (5)

- Page 56 1-6. Main Parts Replacement Lock lever (1) Guide groove 1-6-1. Door Open Lever Replacement Cassette holder 1. Release the claw (1) of the door open lever (2) assembly (2) inserted to the hole at the left lower of the right side mechanical deck with the door open lever (2) turned to the arrow direction.

- Page 57 1-6-4. FL Arm Lever Replacement 1. Remove the door open lever. (Refer to item 1-6-1.) Worm wheel (10) 2. Remove the FL cassette guide assembly. (Refer to Boss (3) of mechanical deck item 1-6-2.) FL cam gear (7) 3. Remove the cassette holder assembly. (Refer to item 1-6-3.) 4.

- Page 58 13. When mounting the FL cam gear (7), align the mark of the FL cam gear (7) with the center of the worm wheel (9). FL cam gear (7) Apply grease to the Mark shaded portion Worm wheel (9) Fig. 1-6-7 FL drive slider Fig.

- Page 59 1-6-6. Worm Gear, Worm Gear Holder, Loading Motor Apply grease to the shaded portion and Worm Wheel Replacement 1. Release the claw (1) of the worm gear holder (2) from the cutout portion of the mechanical deck by bending it to the arrow direction, and remove the worm gear holder (2) by pulling downward.

- Page 60 7. Remove the S, T loading lever assemblies (4) and (5). 8. When removing the pinch drive lever (6), first, remove the cassette door guide, pinch assembly, and the joint lever (Refer to item 1-6-13.), and then remove the T reel table (Refer to item 1-6-11.). Next, pull out the pinch drive lever (6) after turning Apply grease to the it counterclockwise from the bottom side of the...

- Page 61 1-6-8. Tension Lever, Band Brake and Tension Sleeve Replacement 1. Remove the S brake. (Refer to item 1-6-9.) 2. Remove the tension spring (1). 3. Lift up slightly the hole side of the tension sleeve (2) mounted to the mechanical deck, and turn it to the left or right direction, and then remove the tension Tension Tension...

- Page 62 4. Replace each part to new ones. Holder clutch Stop ring (3) assembly (4) 5. Mount it in the reverse order of removal. Notes: • Check that the pad for T brake lever assembly and compression spring (7) are attached. Apply a drop of oil When mounting the T brake lever assembly, do not Spring...

- Page 63 1-6-12. S, T Slider Assemblies Replacement Note: 1. Remove the S, T loading lever assemblies. (Refer to • Check the spring of the holder clutch assembly is set item 1-6-7.) correctly. 2. Remove the S brake. (Refer to item 1-6-9.) 3.

- Page 64 No. 9 guide post (10) Pinch assembly (3) Brim of the Capstan motor Cassette door base. shaft guide (2) No. 9 guide spring Flange of the No.9 Pinch drive guide lever. lever (6) Claw (1) (Without spring) Fig. 1-6-33 Type a Pinch drive spring (7) Small hole Brim of the...

- Page 65 1-6-14. FE Head Replacement 1. Remove screw (1) on the FE head (2), and remove the ACE head Boss (6) of FE head (2). assembly (3) mechanical deck 2. Replace the part with new one. Slit (B) 3. Mount it in the reverse order of removal. 4.

- Page 66 1-6-17. Slip Ring Assembly Replacement Notes: 1. Remove two connectors (1) and (2) (cylinder side and • Take care not to stick the grease, oil and etc. on the PC board side) of the slip ring assembly (3). roller (4). •...

- Page 67 1-6-18. Cylinder Holding Plates Replacement Notes: 1. Remove the head cleaner assembly. (Refer to item 1- • Tightening order of the securing screws (1), (2) and 6-16.) (3) is 294 to 392 mN•m (3 to 4kg•cm). 2. Remove three securing screws (1), (2) and (3) on the •...

- Page 68 Notes: <Replacement> 1. Remove the slip ring assembly. (Refer to item 1-6-17.) • When remounting the cylinder holding plate (4), 2. Remove the head cleaner assembly. (Refer to item 1- after confirming that the FPC (1) is hooked at the 6-16.) groove on the lower head assembly properly, insert 3.

- Page 69 1-6-21. No. 8 Guide Cap Replacement 1. Press the No. 8 guide cap for replacement forcibly after pulling out the No. 8 guide cap (1) from the No. Screws (2) 8 guide (2). 2. Mount the No. 8 guide cap (1) by facing the slant surface to cassette side.

- Page 70 1-7. Check and Adjustment 1-7-2. Reel Torque Check (1) Reel Torque 1-7-1. Check of Tension Post Position 1. REV......supply side Poor torque may not wind the tape. On the other 1. Turn the worm wheel clockwise after removing the cassette holder assembly on the front loading hand, excessive torque will cause damage to the tape mechanism, and set the cam gear at playback mode.

- Page 71 <Precautions for Use of Torque Cassette (KT-300NR)> 1. Before loading a torque cassette in a VCR, always remove tape slack. The tape slack can be removed by rotating the reel in the cassette to its take-up direc- tion. (The tape tends to slack since there is no reel brake on the torque cassette.) 2.

- Page 72 1-7-3. Tape Transport System Adjustment (1) Location of Tape Transport Adjustment The tape transport system has been precisely adjusted in <Adjustment Reference> the factory, so only when some defective phenomenon Lower flange height of No.8 guide is used as the basic occurs such as noise observed on the screen and tape reference for the transport adjustment.

- Page 73 (2) Tape Transport System Adjustment Flowchart Head assembly (cylinder) assembly replacement S, T slider assembly replacement ACE head assembly replacement Impedance roller replacement Capstan motor assembly Tension lever assembly replacement Clutch gear assembly replacement replacement Pinch lever assembly replacement FE head replacement Reel table replacement Checks for Hi-Fi models only.

- Page 74 (3) Tape Transport System Adjustment c. Audio Head Azimuth Adjustment <Rough Adjustment> 1. Play back the 7 kHz audio signal on the alignment When the part(s) listed in Table 1-7-1 is replaced, tape in the SP mode. perform required adjustments by referring to procedures 2.

- Page 75 3) Linearity Adjustment 7. If the envelope varies like NG figures as shown in 1. Play back the SLP mode white video signal on the Fig. 1-7-9, perform the adjustment again since it is alignment tape. abnormal. Smooth secondary curves are allowable level. Note: •...

- Page 76 c. Audio Head Height Check 5) No. 9 Guide Lever Check Play back the audio signal as described in the step 4) a., 1. Set the VCR to Cue mode with T-160 tape (at and check if the audio envelope is flat. If not, repeat the beginning portion) loaded.

- Page 77 7) Envelope Check b. Review mode 1. Make recordings and playback the tapes T-120 and Tape damage at No. 8 guide T-160 in SP and SLP modes and make sure the (a) ACE head assembly rough adjustment playback output envelope meets the specifications (Pinch assembly, No.

- Page 78 1-8. Self-Check Function Table 1-8-2 Abnormal system control modes 1-8-1. Outline Standby Stop When a tape running stops or the VCR enters the power Rewind OFF mode, etc. due to some abnormality, the abnormal- Review ity is stored in the EEPROM and displayed on the display tube.

- Page 79 2. ELECTRICAL ADJUSTMENT < Specified input output levels, and impedance > Video input: Negative sync, standard composite < Test equipment required > video signal 1 V(p-p), 75 Ω Adjustment will be performed with the following test Video output: Same as the video input, equipment.

- Page 80 Alignment tape specifications (1) ST-N1 Item Record Contents Video signal Audio signal Mode Time *Check and adjustment of Servo circuit. Color bar 1 kHz *Check and adjustment of Video circuit. 10 min *Check and adjustment of Audio circuit. Mono Scope 3 kHz *Check and adjustment of Servo circuit.

- Page 81 (3) ST-N5 Item Record Video signal Audio signal Contents Mode Time *Check and adjustment of Servo circuit. Color bar 1 kHz *Check and adjustment of Video circuit. 10 min *Check and adjustment of Audio circuit. Mono Scope 3 kHz *Check and adjustment of Servo circuit. 10 min Notes : 1.

- Page 82 P990 P801 P506 Tuner Power Supply R008 ZX01 Main Board 2-1. PIF Circuit 2-1-1. In Case of IC01 is Replaced When IC01 (µPC1852) is replaced, the EEPROM data in the VCR is required to memorize a new set of default values as initial alignment.

- Page 83 2-2. Servo Circuit 2-2-2. Pseudo-V 2-2-1. Playback Phase (PG) Adjustment Test point : Tracking UP-DOWN key Test equipment : TV monitor Test point : P506, P990 (Video Out) Test equipment : Oscilloscope 1. Self-recorded tape in SP mode is played and enter STILL mode.

- Page 84 General Descriptions Adjustment Procedures General Descriptions Parts List Adjustment Procedures Parts List SECTION 3 SERVICING DIAGRAMS 1. INSPECTION PROCEDURES 2. REMOVAL OF THE CABINET 3. LOCATION OF ELECTRICAL UNITS 4. PC BOARD SERVICING PROCEDURE 5. PART CONFIGURATION AND THEIR SYMBOLS 5-1.

-

Page 85: Inspection Procedures

1. INSPECTION PROCEDURES Fig No. Operation steps Items to be confirmed Inspection block Block Circuit Diagram Diagram 1.AC Plug-in Clock setting Clock display Power (AC system) 7-1-1 8-2-1 Clock setting operation 7-3-1 8-2-1 2.Power SW ON Timer/counter, SP/SLP, TV/ Mode display lamp Power 7-1-1 8-2-1... -

Page 86: Removal Of The Cabinet

2. REMOVAL OF THE CABINET 4. PC BOARD SERVICING PRO- CEDURE (1) Unplug the power supply plug (1) from the outlet. (2) Remove the three screws (3) securing the Top cover When performing service, connect each connection part (2). of the mechanical deck with the main PC board (two (3) Pull the Top cover (2) backwards for removing. -

Page 87: Part Configuration And Their Symbols

5. PART CONFIGURATION AND THEIR SYMBOLS 5-1. Precautions For Part Replacement * In the schematic diagram, parts marked (ex. F801) are critical part to meet the safety regulations, so always use the parts bearing specified part codes (SN) when replacing them. * Using the parts other than those specified shall violate the regulations, and may cause troubles such as operation failures, fire, etc. -

Page 88: Inductor Indication

5-4. Inductor Indication Unit None • • • H µ • • • µH • • • mH Tolerance None • • • ± 5 % • • • ± 0.1 % 10µ • • • ± 0.25 % • • • ± 0.5 % •... -

Page 89: Printed Wiring Board And Schematic Diagram

6. PRINTED WIRING BOARD AND SCHEMATIC DIAGRAM UZ01 MAIN UV01 SP–A W501A P102 COMP EVER +5.6V SP–B F(–) F(+) EP–A EVER +5V SCLK P101 70165319 MAIN TO DIS EP–B HIFI / CTL(+) HIFI / CTL(+) DIS TO MAIN HIFI / CTL–) HIFI / CTL–) REMOTE IN HiFi SA... -

Page 90: Block Diagrams

7. BLOCK DIAGRAMS 7-1. Power Supply Block Diagram T802 C832 RECTIFIER D820 MB 24V SMOOTHING C826 C805 RECTIFIER D826 D802 D804 C806 R803 VKK–26V D803 D805 SMOOTHING L801 D806 ,C813 C827 RECTIFIER D827 RECTIFIER EVER 37V SNUBBER SMOOTHING SMOOTHING C825 D825 F1 (+) RECTIFIER... -

Page 91: Pif Block Diagram

7-2. PIF Block Diagram S001 CH SW 3 IN 1 TUNER ANT IN ANT OUT VIDEO SIGNAL H001 TMDH2–032A AUDIO SIGNAL ANT IN RF OUT AUDIO IN 4.5MHz OSC CH SW RF MODULATOR MB(5V) SPLITER HA11560FP RF SW CONTROL RF VIDEO IN RESONATOR VIDEO IN TO VIDEO... -

Page 92: Kdb Display Block Diagram

7-3. KDB Display Block Diagram ZX01 25U39149SAN F(–) 6G 5G 4G 3G 2G 1G S16S15S14S13S12 S11S10 S9 S8 S7 S6 S5 S4 S3 S2 S1 F(+) 9 10 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 34 35 F(+) F(–) - Page 93 ECO / ECO LED POWER LED Seg 1 Seg 2 Seg 3 Seg 4 Seg 5 IC501 Seg 6 Seg 7 TMP93CU76 Seg 8 Seg 9 Seg 10 MAIN Seg 11 Seg 12 MICROCOMPUTER Seg 13 Seg 14 KEY INPUT 2 KEY INPUT 1 B3 / B4 (Shuttle) B1 / B2 (Shuttle)

- Page 94 – – – – – – – – – 2b,2c – – – – – – – – 3b,3c Fig. 7-3-3...

-

Page 95: Eds Block Diagram

7-4. EDS Block Diagram CSYNC VIDEO IN IC301 Z86131 Buffer HSYNC M.SYNC Dual Logic Clamp Lines 1 Drive COMP SYNC & MUX O / S Buffer SYNC Slicer Control Data Loop Slicer Filter V Lock Vss(A) Digital Data CLK II Logic Recovery Line &... - Page 96 7-5. Servo/Logic Block Diagram IC501 TMP93CU76 EVER +5V MAIN MICROPROCESSOR BU 5.0V EVER +5V D.Vcc AD REF IC505 DRIVE EVER +5V EVER +5V PST7025MT DX32 DX31 RESET IC BU 5.0V QX30, QX31 RMT OUT REC INHIBIT SW S602 REC INH START SENSOR INPUT...

- Page 97 7-5-1. IC501 Main Microcomputer Terminal Function TEST PIN TEST3(ALE) C.SYNC COMPOSITE SYNC INPUT(V SYNC DETECT) NO CONNECTION C.FGA IN CAPSTAN AMPLIFIED FG.A INPUT TV / VCR SWITCH TV / VCR C.FGB IN CAPSTAN AMPLIFIED FG.B INPUT NO CONNECTION POWER GOOD POWER A.C CLOCK INPUT CLOCK OUTPUT SIGNAL TO OSD IC OSD SIO CLK...

- Page 98 7-5-2. IC501 Main Microcomputer Output Polarity IC501 MAIN MICROCOMPUTER OUTPUT POLARITY MODE Un– REMOTE MAIN Pin. SLOT SLOT Load STAND PLAY STILL SLOW Act. Load STOP PAUSE POWER POWER –ing –BY SP SLP SP SLP SP SLP SP SLP SP SLP SP SLP SP SLP –ing...

- Page 99 7-5-3. Logic Mode Shift Table PAUSE / COUNTER REMOCON MAIN COUNTER TAPE TAPE STOP PLAY SLOW EJECT INDEX Current STILL / TIMER POWER POWER RESET START Mode POWER POWER SHORT SHORT STOP – EJECT SEARCH POWER POWER – EJECT STOP POWER POWER REVIEW...

- Page 100 7-6. Video and Conventional Audio Block Diagram PLAYBACK Y SIGNAL PLAY AUDIO Q206 REC AUDIO PLAY VIDEO REC VIDEO MAIN DE–EMPH SYNC W / C O / C C TRAP MAIN EMPH CLAMP VIDEO IN NL–EMPH DE–EMPH DELAY PV / PH REC FM FM–MOD CLAMP...

- Page 101 7-7. Hi-Fi Audio Block Diagram TUNER AUDIO (L) TO PIF TUNER AUDIO (R) I / O I C BUS DECODER MEMORY DECODER MOD AUDIO INPUT SELECTOR SDA1 LINE IN2 (L) BPF ADJ SCL1 LINE IN2 (R) HIFI ENV SERVO / LOGIC HIFI HIFI DET OUT OUTPUT...

- Page 102 7-7-1. Audio Level Chart HIFI AUDIO LEVEL CHART [mV(rms)] [dB] (–8) –10 77.5 –20 (REC / PLAY) 24.5 –30 7.75 –40 2.45 –50 INPUT INPUT PLAY LINE LINE 400Hz SELECTOR OUTPUT SYSTEM INPUT SYSTEM SYSTEM OUTPUT mV(rms) Fig. 7-7-2 CONVENTIONAL AUDIO LEVEL CHART [mV(rms)] [dB] (–8)

- Page 103 8. CIRCUIT DIAGRAMS 8-1. Waveform Power Selvo/Logic Video/Audio Q801, COLLECTOR H001, Pin 1 A-15 ICD01, Pin 16 C-18 IC501, Pin 6 IC501, Pin 50 IC506, Pin 3 IC201, Pin 15 IC201, Pin 59 IC920, Pin 19 K-10 I-12 H-15 CTL. AMP SCAN1 AUDIO IN SCL1...

- Page 104 8-2. Cricuit Diagram Divided Circuit Diagram (For Printing) Note PLAY AUDIO [V] : EE SERVO MODE AUDIO MODE meaning "KETSU" AUDIO (V) : PLAY JP212 LOCATION PLAY LOCATION PLAY (20) JP211 JP253 "Not used". PLAY VIDEO : REC (15) (10) VIDEO V001 JP225...

- Page 105 8-2. Cricuit Diagram JP212 (20) [3.25] (3.27) R210 Q219 [2.33] 3.27 KETSU (2.33) Q211 2.33 C246 2SC2712Y R238 KETSU BUFFER KETSU R212 L207 68µ JP201 (10) R248 [1.67] R211 100R (1.67) 1.5k L206 47µ C276 1.67 JP203 (12.5) C210 C244 R213 R227 2µ...

- Page 106 JP212 JP211 JP253 (20) (15) (10) JP225 D202 L205 (7.5) (10) R243 KETSU 10µ Q214 KETSU KETSU Q215 KETSU KETSU JP238 JP277 (15) (7.5) C203 C202 D201 47µ F0.01µ KETSU R203 JP219 JP234 (7.5) C246 KETSU KETSU JP233 (10) R204 L207 68µ...

- Page 107 Note meaning "KETSU" "Not used". V001 EARTH PLATE P102 R104 3 IN 1 TUNER CH SW R105 H001 TMDH2 C202 D201 (3CH) F0.01µ S001 KETSU RF VIDEO IN JP287 SSSF12 (4CH) ANT IN RF OUT R203 AUDIO IN 23344082 (10) 4.5M OSC CH SW R204...

- Page 108 [V] : EE PLAY AUDIO SERVO MODE AUDIO MODE meaning "KETSU" (V) : PLAY AUDIO LOCATION PLAY LOCATION PLAY : REC used". PLAY VIDEO VIDEO – – – IC502 14.1 14.1 JP305 (20) 14.1 14.1 IC503 14.1 14.1 JP306 (20) IC920 JP010 (20)

- Page 109 JP202 JP246 (12.5) (7.5) ON / OFF5V ON / OFF5V ICL01 TC90A25F–410 Csync IN CL12 F0.01µ KETSU VIDEO IN D GND SERVO A.Vcc LOCATION CL13 BLANK CL11 KETSU KETSU VIDEO OUT D.Vcc Q510 RL11 A GND 1.8k RL13 S.CLK P1 OUT S.DATA IN Q511 1SS131...

- Page 110 LA7116 P246 SERVO MODE 7.5) C545 LOCATION PLAY 47µ16V C–Ref VCC2 32 33 ON / OFF5V R531 4.7k Q515 CR– C547 12.9 11.7 11.7 Q516 C548 R568 R510 C520 RN1402 R532 R511 22µ35V 1.8k 1µ50V Q515 2.2k 1 / 6w SWITCH 4.7k DH11...

- Page 111 AUDIO HIFI C534 PROCESSOR 10µ25V MODE C532 PLAY B0.1µ R522 C533 12.9 11.7 11.7 B0.1µ C531 HW300B(F)–15 R593 B0.1µ Z662 4.7k IC503 TB6515AP DRUM MOTOR DRIVER Z662A C940 HOLD HALLSEN HALL SENSOR 10µ16V EVER 5V END SENSOR JP904 REC FM R572 (7.5) ON / OFF5V...

- Page 112 – – – C971 22µ16V R926 C922 R924 1µ50V R927 IC501 R925 C923 1µ50V (maxi) RF92 CF90 1µ50V RF90 – – – – – – CF91 1µ50V RF93 RF91 (maxi) C929 ON / OFF+9V 10µ16V VIDEO MODE – – – LOCATION PLAY C942...

- Page 113 9. PC BOARDS 9-1. Main PC Board P990 (UK01) S001 R801 C801 P801 Q870 D203 P506 D801 D204 C844 D870 C223 CL11 L202 R870 W101 C270 L206 D803 RL21 T801 X401 C803 L207 C248 C113 C804 L209 L101 CF03 C103 LF01 C002 D804...

- Page 114 9-2. FCB PC Board (UK03) CK99 SK21 WK11 SK22 Fig. 9-2-1 9-3. JSB PC Board (UK03) Fig. 9-3-1...

- Page 115 General Descriptions Adjustment Procedures Servicing Diagrams Servicing Diagrams General Descriptions Adjustment Procedures SECTION 4 PARTS LIST 1. SAFETY PRECAUTION 2. NOTICE 3. ABBREVIATIONS 3-1. Integrated Circuit (IC) 3-2. Capacitor (Cap) 3-3. Resistor (Res) 4. EXPLODED VIEWS 4-1. Packing Assembly 4-2. Cabinet Assembly 4-3.

- Page 116 1. SAFETY PRECAUTION The parts identified by ! ( ) mark are critical for safety. Replace only with part number specified. The mounting position of replacement is to be identical with originals. The substitute replacement parts which do not have the same safety characteristics as specified in the parts list may create shock, fire or other hazards.

- Page 117 4. EXPLODED VIEWS A703 4-1. Packing Assembly A702 P801 Y101 Y102 Y103 Y104 Y107 Y111 Y112 Y113 A701 Fig. 4-1-1 4-2. Cabinet Assembly A104 A104J UK02 A101D A101H A106A A102C UK03 A101 A106 Fig. 4-2-1...

- Page 118 4-3. Chassis Assembly B001A UZ01 Fig. 4-3-1...

- Page 119 4-4. Mechanism Assembly (1) G051 G050 G001 G101A G101 U190 U190A G104 G102 G053 G661 G534 G536 G663 G532 G530 G540 G052 B256 G666 G538 B254 G428 G510 G555 G458 G480 B239 G420 G450 B474 K546 G527 G520 B478 B473 B488 B500 B458...

- Page 120 4-5. Mechanism Assembly (2) K544 K490 K544 K502 K542 K350 K330 B248 K340 K250 K140 K110 K248 B570 B410 K240 K544 K180 B444 B446 K530 B448 B440 B238 B452 K470 B560 KC02 K224 K221 K200 K219 G546 G542 Fig. 4-5-1...

- Page 121 LOCATION PART NUMBER NUMBER DESCRIPTION - MECHANICAL PARTS - ! A101 70884737 Front Panel A101D 70896151 Cassette Door A101H 70356358 Spring A102C 70868910 Door ! A104 70814541 Top Cover A104J 70391703 Screw 3x6mm A105 70896091 Bracket A106 70885253 Knob A106A 70391356 Screw 3x10mm...

- Page 122 LOCATION PART NUMBER NUMBER DESCRIPTION Y104 70061209 Sheet(Extended Service Plan) Y112 70148432 Remote Control Unit Y113 70168298 RF Cable...

- Page 123 LOCATION PART NUMBER NUMBER DESCRIPTION - ELECTRICAL PARTS - UK02 70185130 PC Board Assy - RESISTORS - RF02 24872750 Res,Chip 75ohm J 1/16W RJK91 24000824 Chip Jumper - MISCELLANEOUS - P998 70163114 Phono Jack P999 70163100 Phono Jack PK99 70163113 Phono Jack SK21 70145487...

- Page 124 LOCATION PART NUMBER NUMBER DESCRIPTION - DIODES - D001 23316753 Diode,Zener MTZJ33A D501 A7152750 Diode,Chip 1SS226 D503 23115537 Diode 1SS131 D506 23118486 Diode ERA15-02 D507 23118486 Diode ERA15-02 D508 23118486 Diode ERA15-02 D509 23118486 Diode ERA15-02 D510 23118486 Diode ERA15-02 D601 70115450 Diode,LED...

- Page 125 LOCATION PART NUMBER NUMBER DESCRIPTION C201 24792471 Cap,Electrolytic 470MF M 6.3V C202 24814103 Cap,Chip 0.01MF Z 50V C203 24630850 Cap,Electrolytic 47MF M 16V C204 24814103 Cap,Chip 0.01MF Z 50V C210 24781270 Cap,Chip 27pF J 50V C220 24814103 Cap,Chip 0.01MF Z 50V C222 24815103 Cap,Chip...

- Page 126 LOCATION PART NUMBER NUMBER DESCRIPTION C527 24815103 Cap,Chip 0.01MF K 50V C528 24815103 Cap,Chip 0.01MF K 50V C529 24815103 Cap,Chip 0.01MF K 50V C530 24815103 Cap,Chip 0.01MF K 50V C531 24092178 Cap,Chip 0.1MF K 25V C532 24092178 Cap,Chip 0.1MF K 25V C533 24092178 Cap,Chip...

- Page 127 LOCATION PART NUMBER NUMBER DESCRIPTION C930 24591103 Cap,Plastic 0.01MF J 50V C931 24591103 Cap,Plastic 0.01MF J 50V C932 24794100 Cap,Electrolytic 10MF M 16V C933 24794100 Cap,Electrolytic 10MF M 16V C934 24794100 Cap,Electrolytic 10MF M 16V C935 24794100 Cap,Electrolytic 10MF M 16V C936 24591103 Cap,Plastic...

- Page 128 LOCATION PART NUMBER NUMBER DESCRIPTION R224 24872512 Res,Chip 5.1kohm J 1/16W R225 24872122 Res,Chip 1.2kohm J 1/16W R226 24872152 Res,Chip 1.5kohm J 1/16W R227 24872511 Res,Chip 510ohm J 1/16W R228 24872681 Res,Chip 680ohm J 1/16W R229 24872511 Res,Chip 510ohm J 1/16W R230 24000824 Chip Jumper...

- Page 129 LOCATION PART NUMBER NUMBER DESCRIPTION R568 24366222 Res,Carbon 2.2kohm J 1/6W R569 24366222 Res,Carbon 2.2kohm J 1/6W R570 24872103 Res,Chip 10kohm J 1/16W R571 24366303 Res,Carbon 30kohm J 1/6W R572 24366223 Res,Carbon 22kohm J 1/6W R575 24366472 Res,Carbon 4.7kohm J 1/6W R577 24366223 Res,Carbon...

- Page 130 LOCATION PART NUMBER NUMBER DESCRIPTION R937 24872821 Res,Chip 820ohm J 1/16W RD01 24872102 Res,Chip 1kohm J 1/16W RD02 24872103 Res,Chip 10kohm J 1/16W RD03 24872163 Res,Chip 16kohm J 1/16W RD04 24872683 Res,Chip 68kohm J 1/16W RD05 24872302 Res,Chip 3kohm J 1/16W RD06 24872512 Res,Chip...

- Page 131 LOCATION PART NUMBER NUMBER DESCRIPTION W701A 23902358 Connector,FFC,7P X401 23153359 Crystal 3.579545MHz X501 23153409 Crystal 16MHz X502 70153690 Crystal 32.768MHz Z601 70200448 Photo Interrupter GP1S566 Z602 70200448 Photo Interrupter GP1S566 Z661 70125758 Stator Z662 70114368 Hall Sensor HW300B Z662A 70869627 Holder ZX01 70113184...

- Page 132 438B ALEXANDRA ROAD BLOCK B#06-01 ALEXANDRA TECHNOPARK SINGAPORE 119968...