Siemens SIMATIC ET 200SP Manual

Digital output module dq 4x24vdc/2a hs 6es7132-6bd20-0da0

Hide thumbs

Also See for SIMATIC ET 200SP:

- System manual (320 pages) ,

- Manual (270 pages) ,

- Operating instructions manual (166 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Summary of Contents for Siemens SIMATIC ET 200SP

- Page 2 ___________________ Preface ___________________ Documentation guide ___________________ SIMATIC Product overview ___________________ DQ operating mode DQ (valve control) ET 200SP Digital output module ___________________ Oversampling operating DQ 4x24VDC/2A HS mode (6ES7132-6BD20-0DA0) ___________________ Pulse width modulation operating mode Manual ___________________ Cam control operating mode ___________________ Technical specifications ___________________...

- Page 3 Note the following: WARNING Siemens products may only be used for the applications described in the catalog and in the relevant technical documentation. If products and components from other manufacturers are used, these must be recommended or approved by Siemens. Proper transport, storage, installation, assembly, commissioning, operation and maintenance are required to ensure that the products operate safely and without any problems.

-

Page 4: Preface

Purpose of the documentation This manual complements the system manual ET 200SP distributed I/O system (http://support.automation.siemens.com/WW/view/en/58649293). Functions that generally relate to the system are described in the system manual. The information provided in this manual and in the system/function manuals supports you in commissioning the system. - Page 5 Siemens' products and solutions undergo continuous development to make them more secure. Siemens strongly recommends that product updates are applied as soon as they are available and that the latest product versions are used. Use of product versions that are no longer supported, and failure to apply the latest updates may increase customers' exposure to cyber threats.

-

Page 6: Table Of Contents

Table of contents Preface ..............................3 Documentation guide ..........................7 Product overview ..........................12 Properties ..........................12 DQ operating mode DQ (valve control) ....................18 Wiring ............................18 3.1.1 Wiring and block diagram ....................... 18 Parameters/address space ..................... 21 3.2.1 Normal operation/Valve control .................... - Page 7 Table of contents Interrupts/diagnostics alarms ....................55 5.3.1 Status and error displays ....................... 55 5.3.2 Interrupts ..........................57 5.3.3 Diagnostics alarms ......................... 57 Cam control operating mode ......................... 59 Connecting ..........................59 6.1.1 Wiring and block diagram ...................... 59 Parameters/address space ....................62 6.2.1 Cam control ..........................

-

Page 8: Documentation Guide

Documentation guide The documentation for the SIMATIC ET 200SP distributed I/O system is arranged into three areas. This arrangement enables you to access the specific content you require. Basic information The system manual describes in detail the configuration, installation, wiring and commissioning of the SIMATIC ET 200SP. - Page 9 You can download the product information free of charge from the Internet (https://support.industry.siemens.com/cs/us/en/view/73021864). Manual Collection ET 200SP The Manual Collection contains the complete documentation on the SIMATIC ET 200SP distributed I/O system gathered together in one file. You can find the Manual Collection on the Internet (http://support.automation.siemens.com/WW/view/en/84133942).

- Page 10 ● Manuals, characteristics, operating manuals, certificates ● Product master data You can find "mySupport" - CAx Data in the Internet (http://support.industry.siemens.com/my/ww/en/CAxOnline). Application examples The application examples support you with various tools and examples for solving your automation tasks. Solutions are shown in interplay with multiple components in the system - separated from the focus in individual products.

- Page 11 You can find the SIMATIC Automation Tool on the Internet (https://support.industry.siemens.com/cs/ww/en/view/98161300). PRONETA With SIEMENS PRONETA (PROFINET network analysis), you analyze the plant network during commissioning. PRONETA features two core functions: ● The topology overview independently scans PROFINET and all connected components.

- Page 12 Documentation guide SINETPLAN SINETPLAN, the Siemens Network Planner, supports you in planning automation systems and networks based on PROFINET. The tool facilitates professional and predictive dimensioning of your PROFINET installation as early as in the planning stage. In addition, SINETPLAN supports you during network optimization and helps you to exploit network resources optimally and to plan reserves.

-

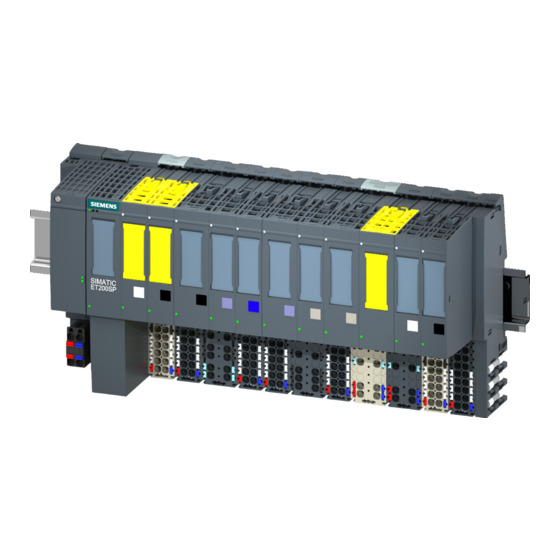

Page 13: Product Overview

Product overview Properties Article number 6ES7132-6BD20-0DA0 View of the module ① ⑧ Module type and name Function class ② ⑨ LED for diagnostics Color coding of module type ③ ⑩ 2D matrix code Function and firmware version ④ ⑪ Terminal diagram Color code for selection of the color coding labels ⑤... - Page 14 Product overview 2.1 Properties Properties The module has the following technical properties: ● Digital output module with 4 outputs (push-pull) ● Source output (PNP, sourcing output) ● Supply voltage L+ ● Output current 2 A (per channel) ● Configurable substitute values (per channel) ●...

- Page 15 Product overview 2.1 Properties STEP 7 GSD file version version Function TIA Portal V5.x PROFINET IO PROFIBUS DP Cam control (MCC - FS01 or V2.0.0 V5.6 HF4 or Modular CAM Control- higher or high- higher ler) Module to module com- FS01 or V2.0.0 V5.6 HF4 or...

- Page 16 Product overview 2.1 Properties Function/Parameter as- Operating mode signment Normal operation Valve Pulse width Oversampling control in normal modulation control operation Parameter assignment Holding time valve control Pulse width modulation duty cycle Pulse width modulation time period Substitute value duty cycle Pulsed cam output duty cycle Pulsed cam output period...

- Page 17 Product overview 2.1 Properties Configuration options You can configure the module with STEP 7 or with a GSD file. When you configure the module using a GSD file, you can find the configuration under various short designations/module names. Depending on the configuration, additional/different addresses are assigned in the process image output/input.

- Page 18 ● Reference identification label ● Shield connector See also You can find more information on accessories in the ET 200SP distributed I/O system (https://support.industry.siemens.com/cs/ww/en/view/58649293) system manual. See also Technical specifications (Page 90) Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0) Manual, 06/2018, A5E32855695-AC...

-

Page 19: Dq Operating Mode Dq (Valve Control)

In this section, you can find the block diagram of the DQ 4x24VDC/2A HS module showing the terminal assignments for a 2-wire and 3-wire connection in DQ operating mode. You can find information on wiring the BaseUnit in the ET 200SP distributed I/O system (https://support.industry.siemens.com/cs/ww/en/view/58649293) system manual. Note You can connect 2 actuators per output. - Page 20 DQ operating mode DQ (valve control) 3.1 Wiring Connection: 2-wire connection of actuators The figure below shows an example for the terminal assignment of the digital output module DQ 4×24VDC/2A HS on the BaseUnit BU type A0 without AUX terminals (2-wire connection).

- Page 21 DQ operating mode DQ (valve control) 3.1 Wiring Connection: 3-wire connection of actuators The figure below shows an example for the terminal assignment of the digital output module DQ 4×24VDC/2A HS on the BaseUnit BU type A0 with AUX terminals (3-wire connection). ①...

-

Page 22: Parameters/Address Space

DQ operating mode DQ (valve control) 3.2 Parameters/address space Parameters/address space 3.2.1 Normal operation/Valve control Normal operation "Normal operation" refers to the function of the DQ 4×24VDC/2A HS as digital output module. Valve control is a special function of normal operation. Valve control function You can use the valve control function to switch to a lower "holding current"... - Page 23 DQ operating mode DQ (valve control) 3.2 Parameters/address space Chronological sequence The figure below shows the chronological sequence for valve control. The pulse width modulation is activated in the next possible data cycle. ① Data cycle ② Holding time valve control Figure 3-3 Valve control "Pulse width modulation time period"...

-

Page 24: Parameters

DQ operating mode DQ (valve control) 3.2 Parameters/address space 3.2.2 Parameters DQ 4×24VDC/2A HS parameters The effective range of the assignable parameters depends on the type of configuration. The following configurations are possible: ● Central operation on an ET 200SP CPU or on an ET 200SP Open Controller ●... -

Page 25: Time Period

DQ operating mode DQ (valve control) 3.2 Parameters/address space Parameter Value range Default Configura- Effective range with configura- tion tion software in RUN HSP0127 for GSD file STEP 7 PROFIBUS (TIA Portal); HSP0230 for STEP 7; GSD file PROFINET IO Holding time 500 ms Channel... -

Page 26: Explanation Of Parameters

DQ operating mode DQ (valve control) 3.2 Parameters/address space 3.2.3 Explanation of parameters Operating mode At the module level, specifies the operating mode in which the module's channels are operated. When configuring with HSP0230 for STEP 7 or with a GSD file, you determine the operating mode when you select the module name. -

Page 27: Address Space

BaseUnits are supplied via the light BaseUnits. The potential group ends at a new light BaseUnit or the end of the station. See also ET 200SP distributed I/O system (http://support.automation.siemens.com/WW/view/en/58649293) 3.2.4 Address space Address space for configuration as a 4-channel DQ 4×24VDC/2A HS The figure below shows the assignment of the address space for the configuration as a 4-channel module with value status (normal operation without/with valve control). -

Page 28: Interrupts/Diagnostics Alarms

DQ operating mode DQ (valve control) 3.3 Interrupts/diagnostics alarms Evaluating the value status If you enable the value status for the digital module, a byte in the input address space is additionally assigned. Bits 0 to 3 of this byte are each assigned to one channel. They provide information about the validity of the digital value. - Page 29 DQ operating mode DQ (valve control) 3.3 Interrupts/diagnostics alarms Meaning of the LEDs The following tables contain the meaning of the Status and error displays. Corrective measures for diagnostics alarms can be found in the section Diagnostics alarms. DIAG LED Table 3- 2 Error display of the DIAG LED DIAG LED...

-

Page 30: Interrupts

DQ operating mode DQ (valve control) 3.3 Interrupts/diagnostics alarms PWR LED Table 3- 5 Status display of the PWR LED PWR LED Meaning No supply voltage L+ Supply voltage L+ present 3.3.2 Interrupts The DQ 4×24VDC/2A HS digital output module supports diagnostic interrupts. Diagnostic interrupts The module generates a diagnostic interrupt at the following events: ●... - Page 31 DQ operating mode DQ (valve control) 3.3 Interrupts/diagnostics alarms Table 3- 6 Diagnostics alarms, their meaning and corrective measures Diagnostics alarms Error code Meaning Solution Short circuit Short-circuit of the actuator supply Correct the process wiring Excess temperature The module has detected that the maxi- Correct the process wiring mum permitted module temperature has been exceeded.

-

Page 32: Oversampling Operating Mode

2-wire and 3-wire connection in oversampling operating mode. You can find information on wiring the BaseUnit in the ET 200SP distributed I/O system (https://support.industry.siemens.com/cs/ww/en/view/58649293) system manual. Note You can connect 2 actuators per output. Note Cross circuit at output Be aware that voltage from a cross circuit at the output can feed L+ to modules. - Page 33 Oversampling operating mode 4.1 Connecting Connection: 2-wire connection of actuators The figure below shows an example for the terminal assignment of the digital output module DQ 4×24VDC/2A HS on the BaseUnit BU type A0 without AUX terminals (2-wire connection). ① 2-wire connection 24 V DC Supply voltage L+ (infeed for light BaseUnit...

- Page 34 Oversampling operating mode 4.1 Connecting Connection: 3-wire connection of actuators The figure below shows an example for the terminal assignment of the digital output module DQ 4×24VDC/2A HS on the BaseUnit BU type A0 with AUX terminals (3-wire connection). ① 3-wire connection 1 A ...

-

Page 35: Parameters/Address Space

Oversampling operating mode 4.2 Parameters/address space Parameters/address space 4.2.1 Oversampling Function Oversampling is the output of data in constant bus cycle segments (sub-cycles), whereby n sub-cycles correspond to one PROFINET bus cycle. A data packet is transmitted from the controller to the module, which outputs the packet in n constant bus sub-cycles. Oversampling is useful whenever you require output of data with high time resolution but without using an extremely short PROFINET bus cycle and thus fast CPU cycles. -

Page 36: Parameters

Oversampling operating mode 4.2 Parameters/address space Chronological sequence The figure below shows the chronological sequence for oversampling. The output data present in the CPU is output in the data cycle after the next one, distributed across the sub- cycles which are generated on the actual module. Output values from bus cycle n Sub- 4 bit x 32 (max) each = max. - Page 37 Oversampling operating mode 4.2 Parameters/address space The following parameter settings are possible: Table 4- 1 Assignable parameters in oversampling operating mode Parameter Value range Default Configuration Effective range in RUN with configuration software HSP0127 for STEP 7 (TIA Portal); HSP0230 for STEP 7 Operating mode Module...

-

Page 38: Explanation Of Parameters

BaseUnits are supplied via the light BaseUnits. The potential group ends at a new light BaseUnit or the end of the station. See also Distributed I/O System ET 200SP (https://support.industry.siemens.com/cs/ww/en/view/58649293) Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0) Manual, 06/2018, A5E32855695-AC... -

Page 39: Address Space

Oversampling operating mode 4.2 Parameters/address space 4.2.4 Address space Address space for configuration with oversampling The figure below shows the address space allocation for the configuration with oversampling. Figure 4-4 Address space of the DQ 4×24VDC/2A HS with oversampling Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0) Manual, 06/2018, A5E32855695-AC... -

Page 40: Interrupts/Diagnostics Alarms

Oversampling operating mode 4.3 Interrupts/diagnostics alarms Interrupts/diagnostics alarms 4.3.1 Status and error displays LED displays The figure below shows the location of the LED displays of the DQ 4×24VDC/2A HS. ① DIAG (green/red) ② Channel status (green) ③ OVS (green) ④... - Page 41 Oversampling operating mode 4.3 Interrupts/diagnostics alarms Meaning of the LEDs The following tables contain the meaning of the Status and error displays. Corrective measures for diagnostics alarms can be found in the section Diagnostics alarms. DIAG LED Table 4- 2 Error display of the DIAG LED DIAG LED Meaning...

-

Page 42: Interrupts

Oversampling operating mode 4.3 Interrupts/diagnostics alarms PWR LED Table 4- 5 Status display of the PWR LED PWR LED Meaning No supply voltage L+ Supply voltage L+ present 4.3.2 Interrupts The DQ 4×24VDC/2A HS digital output module supports diagnostic interrupts. Diagnostic interrupts The module generates a diagnostic interrupt at the following events: ●... - Page 43 Oversampling operating mode 4.3 Interrupts/diagnostics alarms Table 4- 6 Diagnostics alarms, their meaning and corrective measures Diagnostics alarms Error code Meaning Solution Short circuit Short-circuit of the actuator supply Correct the process wiring Excess temperature The module has detected that the maxi- Correct the process wiring mum permitted module temperature has been exceeded.

-

Page 44: Pulse Width Modulation Operating Mode

2-wire and 3-wire connection in pulse width modulation operating mode. You can find information on wiring the BaseUnit in the ET 200SP distributed I/O system (https://support.industry.siemens.com/cs/ww/en/view/58649293) system manual. Note You can connect 2 actuators per output. - Page 45 Pulse width modulation operating mode 5.1 Connecting Connection: 2-wire connection of actuators The figure below shows an example for the terminal assignment of the digital output module DQ 4×24VDC/2A HS on the BaseUnit BU type A0 without AUX terminals (2-wire connection).

- Page 46 Pulse width modulation operating mode 5.1 Connecting Connection: 3-wire connection of actuators The figure below shows an example for the terminal assignment of the digital output module DQ 4×24VDC/2A HS on the BaseUnit BU type A0 with AUX terminals (3-wire connection). ①...

-

Page 47: Parameters/Address Space

Pulse width modulation operating mode 5.2 Parameters/address space Parameters/address space 5.2.1 Pulse width modulation Function In the "pulse width modulation" operating mode, the four outputs only provide a pulse width modulated output signal. The digital channel is activated with a pulse duty cycle that is updated cyclically as a function of the output value from the user program. - Page 48 Pulse width modulation operating mode 5.2 Parameters/address space Chronological sequence The output value (0 ... 1000) is written from the user program to the output word of the channel. The module maps this value by means of the output characteristic and the values for minimum pulse duration and minimum pulse pause to the configured time period and thus determines the pulse duty cycle (the pulse duration) of the pulse width modulation.

- Page 49 Pulse width modulation operating mode 5.2 Parameters/address space The minimum pulse duration and the minimum pulse pause are at least 2 μs each, which means: ● Any pulse duration that is shorter than the minimum pulse duration will be suppressed ●...

-

Page 50: Parameters

Pulse width modulation operating mode 5.2 Parameters/address space Time period parameter Frequency Output value in the user Pulse duty cycle at output program (‰) terminal DQ (‰) 10.67 ms 94 Hz 0...1000 0...1000 21.33 ms 47 Hz 0...1000 0...1000 34.13 ms 29 Hz 0...1000 0...1000... - Page 51 Pulse width modulation operating mode 5.2 Parameters/address space The following parameter settings are possible for the respective operating mode: Table 5- 2 Assignable parameters in pulse width modulation operating mode (GSD file) Parameter Value range Default Configura- Effective range with configura- tion tion software in RUN...

- Page 52 Pulse width modulation operating mode 5.2 Parameters/address space Parameter Value range Default Configura- Effective range with configura- tion tion software in RUN HSP0127 for GSD file STEP 7 (TIA PROFIBUS Portal); HSP0230 for STEP 7; GSD file PROFINET IO Pulse width modulation 0.93 ms Channel Channel...

-

Page 53: Explanation Of Parameters

Pulse width modulation operating mode 5.2 Parameters/address space 5.2.3 Explanation of parameters Operating mode At the module level, specifies the operating mode in which the module's channels are operated. When configuring with HSP0230 for STEP 7 or with a GSD file, you determine the operating mode when you select the module name. - Page 54 The potential group ends at a new light BaseUnit or the end of the station. Derating Read the information on derating of the module in section Derating of the DQ 4x24VDC/2A HS (Page 95). See also Distributed I/O System ET 200SP (https://support.industry.siemens.com/cs/ww/en/view/58649293) Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0) Manual, 06/2018, A5E32855695-AC...

-

Page 55: Address Space

Pulse width modulation operating mode 5.2 Parameters/address space 5.2.4 Address space Address space for configuration with pulse width modulation The figure below shows the address space allocation for the configuration with pulse width modulation. Figure 5-6 Address space of the DQ 4×24VDC/2A HS with pulse width modulation Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0) Manual, 06/2018, A5E32855695-AC... -

Page 56: Interrupts/Diagnostics Alarms

Pulse width modulation operating mode 5.3 Interrupts/diagnostics alarms Interrupts/diagnostics alarms 5.3.1 Status and error displays LED displays The figure below shows the location of the LED displays of the DQ 4×24VDC/2A HS. ① DIAG (green/red) ② Channel status (green) ③ OVS (green) ④... - Page 57 Pulse width modulation operating mode 5.3 Interrupts/diagnostics alarms Meaning of the LEDs The following tables contain the meaning of the Status and error displays. Corrective measures for diagnostics alarms can be found in the section Diagnostics alarms. DIAG LED Table 5- 3 Error display of the DIAG LED DIAG LED Meaning...

-

Page 58: Interrupts

Pulse width modulation operating mode 5.3 Interrupts/diagnostics alarms PWR LED Table 5- 6 Status display of the PWR LED PWR LED Meaning No supply voltage L+ Supply voltage L+ present 5.3.2 Interrupts The DQ 4×24VDC/2A HS digital output module supports diagnostic interrupts. Diagnostic interrupts The module generates a diagnostic interrupt at the following events: ●... - Page 59 Pulse width modulation operating mode 5.3 Interrupts/diagnostics alarms Table 5- 7 Diagnostics alarms, their meaning and corrective measures Diagnostics alarms Error code Meaning Solution Short circuit Short-circuit of the actuator supply Correct the process wiring Excess temperature The module has detected that the maxi- Correct the process wiring mum permitted module temperature has been exceeded.

-

Page 60: Cam Control Operating Mode

2-wire and 3-wire connection in cam control operating mode. You can find information on wiring the BaseUnit in the ET 200SP distributed I/O system (https://support.industry.siemens.com/cs/ww/en/view/58649293) system manual. Note You can connect 2 actuators per output. - Page 61 Cam control operating mode 6.1 Connecting Connection: 2-wire connection of actuators The figure below shows an example for the terminal assignment of the digital output module DQ 4×24VDC/2A HS on the BaseUnit BU type A0 without AUX terminals (2-wire connection). ①...

- Page 62 Cam control operating mode 6.1 Connecting Connection: 3-wire connection of actuators The figure below shows an example for the terminal assignment of the digital output module DQ 4×24VDC/2A HS on the BaseUnit BU type A0 with AUX terminals (3-wire connection). ①...

-

Page 63: Parameters/Address Space

Cam control operating mode 6.2 Parameters/address space Parameters/address space 6.2.1 Cam control Function In "Cam control" operating mode, switching signals are generated dependent on an encoder value. The axis can be executed as: ● Linear axis ● Rotary axis with modulo function The ET 200SP distributed I/O system determines the current actual position value of the axis using an encoder that is connected to an encoder module, e.g. -

Page 64: Pulsed Cam Output Duty

Cam control operating mode 6.2 Parameters/address space Configuration You configure the cam control with the following parameters: ● "Cam control" operating mode ● Modulo activated ● Encoder module ● Hysteresis ● Axis reference position ● Minimum encoder value/Maximum encoder value ●... - Page 65 Cam control operating mode 6.2 Parameters/address space The configured range of the cam (cam start and end positions and effective direction) is compared with the encoder value, and the switching state (0/1) of the digital output (cam track) is generated based on the result of the comparison. Note Incorrect switching operation due to increment jumps Increment jumps can occur if, due to the system, an encoder value is not transferred to the...

- Page 66 Cam control operating mode 6.2 Parameters/address space Effective direction A cam can be switched as a function of the motion direction. The following effective directions are possible for the cams: None: The cam is not evaluated. Positive: Switching behavior for effective direction "Positive" ●...

- Page 67 Cam control operating mode 6.2 Parameters/address space Negative: Switching behavior for effective direction "Negative": ● The cam switches on when the end position is reached in the negative motion direction ① ● The cam switches off when the start position is crossed in the negative motion direction ②...

- Page 68 Cam control operating mode 6.2 Parameters/address space Hysteresis Fluctuations of the position value of an axis can cause unwanted switching on and off in the cam control. Such unwanted switching states can be suppressed by configuring a hysteresis (> 0). The hysteresis is a position tolerance within which the position values may vary without changing the switching state of the cam.

- Page 69 Cam control operating mode 6.2 Parameters/address space The following example shows the effects of the hysteresis on the switching behavior of the cam with positive effective direction. The hysteresis keeps the output stable when the encoder value signals a small direction reversal. For better orientation, lines are shown for the signal changes.

- Page 70 Cam control operating mode 6.2 Parameters/address space Pulsed cam output It is possible to pulse the cams. This function can be activated via a control interface and is active while a cam has state 1. You configure the pulsed cam output with the "Pulsed cam output duty cycle"...

-

Page 71: Parameters

Cam control operating mode 6.2 Parameters/address space 6.2.2 Parameters Parameters The effective range of the assignable parameters depends on the type of configuration. The following configurations are possible: ● Distributed operation on PROFINET IO in an ET 200SP system In addition to assigning parameters with the configuration software, you can also set the parameters in RUN mode (dynamically) using the user program. - Page 72 Cam control operating mode 6.2 Parameters/address space Parameter Value range Default Configuration Effective range in RUN with configuration software GSD file PROFINET IO Encoder module DI 8x24VDC HS, Module DI 8x24VDC HS, Count, Ch.0 • Count, Ch.0 DI 8x24VDC HS, Count, Ch.1 •...

- Page 73 Cam control operating mode 6.2 Parameters/address space Parameter Value range Default Configuration Effective range in RUN with configuration software GSD file PROFINET IO Channel activated Enable Channel Disable • Enable • Reaction to CPU STOP Shutdown Channel Shutdown • Keep last value •...

- Page 74 Cam control operating mode 6.2 Parameters/address space The following parameters are possible for the module to module communication (MtM) Table 6- 2 Assignable parameters for module to module communication (MtM) Parameters Value range Default Configura- Effective range tion with configuration in RUN software GSD file...

-

Page 75: Explanation Of Parameters

Cam control operating mode 6.2 Parameters/address space 6.2.3 Explanation of parameters 6.2.3.1 Parameters in cam control operating mode Operating mode At the module level, specifies the operating mode in which the module's channels are operated. When configuring using a GSD file, you determine the operating mode when you select the module name. - Page 76 Cam control operating mode 6.2 Parameters/address space Modulo activated When "Modulo" is activated (value = 1), the encoder value is mapped onto a recurring modulo range. The modulo range is defined by the start value and the length. The start value corresponds to the "Minimum encoder value"...

- Page 77 Cam control operating mode 6.2 Parameters/address space The value status of the encoder module affects the value status of the DQ4HS module. If the value status of the encoder module is invalid, the value status of the DQ4HS module is set to For encoder modules that do not provide a direction in the encoder data, it must be kept in mind that only 2 valid different encoder values have to be available in the cam control before the internal direction detection can evaluate the encoder value and the associated...

- Page 78 Cam control operating mode 6.2 Parameters/address space Cam 0 start position/end position to Cam 15 start position/end position The position values are used to specify the switching range of the cam that, in combination with the effective direction and channel assignment, leads to the switching action at the output.

-

Page 79: Parameters For Module To Module Communication (Mtm)

BaseUnits are supplied via the light BaseUnits. The potential group ends at a new light BaseUnit or the end of the station. See also Distributed I/O System ET 200SP (https://support.industry.siemens.com/cs/ww/en/view/58649293) 6.2.3.2 Parameters for module to module communication (MtM) Slot of encoder module... -

Page 80: Address Space

Cam control operating mode 6.2 Parameters/address space 6.2.4 Address space 6.2.4.1 Assignment of the control interface Control interface The user program uses the control interface to influence the behavior of the cam control. The figure below shows the address space allocation for the control interface in the process image output. -

Page 81: Notes On The Control Interface

Cam control operating mode 6.2 Parameters/address space 6.2.4.2 Notes on the control interface Notes on the control bits Table 6- 4 Details for the control interface Control bit Notes SLOT You use this value to specify the write accesses for the registers addressable with LD_SLOT. ACCESS_SLOT •... - Page 82 Cam control operating mode 6.2 Parameters/address space Value of Register Notes LD_SLOT 0x06 DIFF_MEDIAN Read: Averaged difference value of the incoming encoder values (indicator for update rate) The evaluation is directly coupled to the raw value (encoder data). Only the differences between the encoder values as a moving average are evalu- •...

-

Page 83: Assignment Of The Feedback Interface

Cam control operating mode 6.2 Parameters/address space 6.2.4.3 Assignment of the feedback interface Feedback interface The user program receives current values and status information from the module via the feedback interface. The figure below shows the address space allocation for the feedback interface in the process image input. - Page 84 Cam control operating mode 6.2 Parameters/address space Figure 6-13 Assignment of the feedback interface, part 2 Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0) Manual, 06/2018, A5E32855695-AC...

-

Page 85: Notes On The Feedback Interface

Cam control operating mode 6.2 Parameters/address space 6.2.4.4 Notes on the feedback interface Notes on the feedback bits Table 6- 6 Details for the feedback interface Feedback bit Notes ACT_INP Internal encoder value This value is used by the cam control unit of the digital output module for evaluating the configured cams. - Page 86 Cam control operating mode 6.3 Interrupts/diagnostics alarms Feedback bit Notes STS_CAM Signal status of the cam tracks Bit 0 for channel 0: 0 = Cam track off, 1 = Cam track on • Bit 1 for channel 1: 0 = Cam track off, 1 = Cam track on •...

-

Page 87: 6.3 Interrupts/Diagnostics Alarms

Cam control operating mode 6.3 Interrupts/diagnostics alarms Interrupts/diagnostics alarms 6.3.1 Status and error displays LED displays The figure below shows the location of the LED displays of the DQ 4×24VDC/2A HS. ① DIAG (green/red) ② Channel status (green) ③ OVS (green) ④... - Page 88 Cam control operating mode 6.3 Interrupts/diagnostics alarms Meaning of the LEDs The following tables contain the meaning of the Status and error displays. Corrective measures for diagnostics alarms can be found in the section Diagnostics alarms. DIAG LED Table 6- 7 Error display of the DIAG LED DIAG LED Meaning...

-

Page 89: Interrupts

Cam control operating mode 6.3 Interrupts/diagnostics alarms PWR LED Table 6- 10 Status display of the PWR LED PWR LED Meaning No supply voltage L+ Supply voltage L+ present 6.3.2 Interrupts The DQ 4×24VDC/2A HS digital output module supports diagnostic interrupts. Diagnostic interrupts The module generates a diagnostic interrupt at the following events: ●... -

Page 90: Diagnostics Alarms

Cam control operating mode 6.3 Interrupts/diagnostics alarms 6.3.3 Diagnostics alarms Diagnostics alarms A diagnostics alarm is output and the DIAG LED flashes on the module for each diagnostics event. You can read out the diagnostics alarms, for example, in the diagnostics buffer of the CPU. -

Page 91: Technical Specifications

Technical specifications Technical specifications Technical specifications of the DQ 4×24VDC/2A HS Article number 6ES7132-6BD20-0DA0 General information Product type designation DQ 4x24 V DC/2 A HS Firmware version V2.0 FW update possible • usable BaseUnits BU type A0 Color code for module-specific color identifica- CC00 tion plate Product function... - Page 92 Technical specifications 7.1 Technical specifications Article number 6ES7132-6BD20-0DA0 Input current Current consumption, max. 50 mA; without load Output voltage Rated value (DC) 24 V Power loss Power loss, typ. 2.5 W; at 24 V, 25 °C, DQ mode, 2 A per channel Address area Address space per module 1 byte;...

- Page 93 Technical specifications 7.1 Technical specifications Article number 6ES7132-6BD20-0DA0 Digital output functions, parameterizable Switching tripped by comparison values • – Number of cam tracks, max. – Number of cams per module, max. – Number of cams per track, max. Linear axes and rotary axes with modulo function –...

- Page 94 Technical specifications 7.1 Technical specifications Article number 6ES7132-6BD20-0DA0 Switching frequency 5 kHz with resistive load, max. • 5 kHz with inductive load, max. • 5 kHz on lamp load, max. • Total current of the outputs Current per channel, max. •...

- Page 95 0 °C (without condensation) 50 °C vertical installation, max. • Dimensions Width 15 mm Height 73 mm Depth 58 mm Weights Weight, approx. 31 g Dimension drawing See manual ET 200SP BaseUnits (http://support.automation.siemens.com/WW/view/en/58532597/133300) Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0) Manual, 06/2018, A5E32855695-AC...

-

Page 96: Derating Of The Dq 4X24Vdc/2A Hs

Technical specifications 7.2 Derating of the DQ 4x24VDC/2A HS Derating of the DQ 4x24VDC/2A HS Maximum permitted output current depending on the frequency The figure below shows the maximum permitted output current per channel depending on the frequency. You must take this characteristic into consideration for all operating modes of the module. Figure 7-1 Derating of the DQ 4×24VDC/2A HS depending on the frequency Maximum permitted output current depending on the ambient temperature... - Page 97 Technical specifications 7.2 Derating of the DQ 4x24VDC/2A HS DQ derating The figure below shows the maximum permitted total current depending on the ambient temperature for the DQ derating. ① Horizontal installation position ② Vertical installation position Figure 7-2 Additional DQ derating depending on the ambient temperature Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0) Manual, 06/2018, A5E32855695-AC...

- Page 98 Technical specifications 7.2 Derating of the DQ 4x24VDC/2A HS PWM derating The figure below shows the maximum permitted total current depending on the ambient temperature for the PWM derating. ① Horizontal installation position ② Vertical installation position Figure 7-3 Additional PWM derating depending on the ambient temperature Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0) Manual, 06/2018, A5E32855695-AC...

-

Page 99: Parameter Data Records

Parameter data records Parameter assignment and structure of the parameter data record for DQ operating mode Parameter assignment in the user program You can reassign the parameters of the module in RUN. For example, the reaction to CPU STOP of individual channels can be changed in RUN without this having an effect on the other channels. - Page 100 Parameter data records A.1 Parameter assignment and structure of the parameter data record for DQ operating mode Structure of data record 128 for entire module Figure A-1 Structure of data record 128 for entire module Header information The figure below shows the structure of the header information. Figure A-2 Header information Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0)

- Page 101 Parameter data records A.1 Parameter assignment and structure of the parameter data record for DQ operating mode Module header information The figure below shows the structure of the module header information. Figure A-3 Module header information Module parameter block The figure below shows the structure of the module parameter block for channels 0 to 3. Enable a parameter by setting the corresponding bit to "1".

- Page 102 Parameter data records A.1 Parameter assignment and structure of the parameter data record for DQ operating mode Channel parameter block The figure below shows the structure of the channel parameter block. Enable a parameter by setting the corresponding bit to "1". Figure A-6 Structure of byte x to x+7 for channels 0 to 3 Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0)

- Page 103 Parameter data records A.1 Parameter assignment and structure of the parameter data record for DQ operating mode Codes for time period of the pulse width modulation The following table contains the codes for the time period of the pulse width modulation of the digital output module.

- Page 104 Parameter data records A.1 Parameter assignment and structure of the parameter data record for DQ operating mode Error code in the STATUS parameter (hexadeci- Meaning Solution mal) Byte 0 Byte 1 Byte 2 Byte 3 Error in the header, length or number of Correct the length and number of parame- parameter blocks ter blocks, see Figure A-2 Header infor-...

-

Page 105: Parameter Assignment And Structure Of The Parameter Data Record For Oversampling Operating Mode

Parameter data records A.2 Parameter assignment and structure of the parameter data record for oversampling operating mode Parameter assignment and structure of the parameter data record for oversampling operating mode Parameter assignment in the user program You can reassign the parameters of the module in RUN. For example, the reaction to CPU STOP of individual channels can be changed in RUN without this having an effect on the other channels. - Page 106 Parameter data records A.2 Parameter assignment and structure of the parameter data record for oversampling operating mode Structure of data record 128 for entire module Figure A-7 Structure of data record 128 for entire module Header information The figure below shows the structure of the header information. Figure A-8 Header information Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0)

- Page 107 Parameter data records A.2 Parameter assignment and structure of the parameter data record for oversampling operating mode Module header information The figure below shows the structure of the module header information. Figure A-9 Module header information Module parameter block The figure below shows the structure of the module parameter block for channels 0 to 3. Enable a parameter by setting the corresponding bit to "1".

- Page 108 Parameter data records A.2 Parameter assignment and structure of the parameter data record for oversampling operating mode Channel parameter block The figure below shows the structure of the channel parameter block. Enable a parameter by setting the corresponding bit to "1". Figure A-12 Structure of byte x to x+7 for channels 0 to 3 Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0)

- Page 109 Parameter data records A.2 Parameter assignment and structure of the parameter data record for oversampling operating mode Codes for the output rate The table below contains the codes for the output rate of the digital output module. You must enter these codes in byte 4 of the module parameter block of data record 128 (see figure). Table A- 3 Codes for the output rate Value...

- Page 110 Parameter data records A.2 Parameter assignment and structure of the parameter data record for oversampling operating mode The following table shows the module-specific error codes and their meaning for data record 128. The error codes are supported starting from firmware version V2.0.0. Table A- 4 Error messages, their meaning and corrective measures Error code in the...

-

Page 111: Parameter Assignment And Structure Of The Parameter Data Record For Pulse Width Modulation Operating Mode

Parameter data records A.3 Parameter assignment and structure of the parameter data record for pulse width modulation operating mode Parameter assignment and structure of the parameter data record for pulse width modulation operating mode Parameter assignment in the user program You can reassign the parameters of the module in RUN. - Page 112 Parameter data records A.3 Parameter assignment and structure of the parameter data record for pulse width modulation operating mode Structure of data record 128 for entire module Figure A-13 Structure of data record 128 for entire module Header information The figure below shows the structure of the header information. Figure A-14 Header information Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0)

- Page 113 Parameter data records A.3 Parameter assignment and structure of the parameter data record for pulse width modulation operating mode Module header information The figure below shows the structure of the module header information. Figure A-15 Module header information Module parameter block The figure below shows the structure of the module parameter block for channels 0 to 3.

- Page 114 Parameter data records A.3 Parameter assignment and structure of the parameter data record for pulse width modulation operating mode Channel parameter block The figure below shows the structure of the channel parameter block. Enable a parameter by setting the corresponding bit to "1". Figure A-18 Structure of byte x to x+7 for channels 0 to 3 Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0)

- Page 115 Parameter data records A.3 Parameter assignment and structure of the parameter data record for pulse width modulation operating mode Codes for time period of the pulse width modulation The following table contains the codes for the time period of the pulse width modulation of the digital output module.

- Page 116 Parameter data records A.3 Parameter assignment and structure of the parameter data record for pulse width modulation operating mode Error code in the STATUS parameter (hexadeci- Meaning Solution mal) Byte 0 Byte 1 Byte 2 Byte 3 Error in the header, length or number of Correct the length and number of parame- parameter blocks ter blocks, see Figure A-14 Header infor-...

-

Page 117: Parameter Assignment And Structure Of The Parameter Data Record For Cam Control Operating Mode

Parameter data records A.4 Parameter assignment and structure of the parameter data record for cam control operating mode Parameter assignment and structure of the parameter data record for cam control operating mode Parameter assignment in the user program You can reassign the parameters of the module in RUN. For example, you can change the period of individual channels in RUN without this having an effect on the other channels. - Page 118 Parameter data records A.4 Parameter assignment and structure of the parameter data record for cam control operating mode Structure of data record 128 for entire module Figure A-19 Structure of data record 128 for entire module with cam control operating mode Header information The figure below shows the structure of the header information.

- Page 119 Parameter data records A.4 Parameter assignment and structure of the parameter data record for cam control operating mode Module header information The figure below shows the structure of the module header information. Figure A-21 Module header information in cam control operating mode Module parameter block The figure below shows the structure of the module parameter block for channels 0 to 3.

- Page 120 Parameter data records A.4 Parameter assignment and structure of the parameter data record for cam control operating mode Internal block cam control (Modular CAM Controller) The figure below shows the structure of the internal block cam control (Modular CAM Controller). Figure A-24 Internal block cam control (Modular CAM Controller), part 1 Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0)

- Page 121 Parameter data records A.4 Parameter assignment and structure of the parameter data record for cam control operating mode Figure A-25 Internal block cam control (Modular CAM Controller), part 2 Channel header information The figure below shows the structure of the channel header information. Figure A-26 Channel header information in cam control operating mode Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0)

- Page 122 Parameter data records A.4 Parameter assignment and structure of the parameter data record for cam control operating mode Channel parameter block The figure below shows the structure of the channel parameter block. Enable a parameter by setting the corresponding bit to "1". Figure A-27 Structure of byte x to x+7 for channels 0 to 3 in cam control operating mode Digital output module DQ 4x24VDC/2A HS (6ES7132-6BD20-0DA0)

- Page 123 Parameter data records A.4 Parameter assignment and structure of the parameter data record for cam control operating mode Codes for pulsed cam output period The table below contains the codes for the pulsed cam output period of the digital output module.

- Page 124 Parameter data records A.4 Parameter assignment and structure of the parameter data record for cam control operating mode Error code in the STATUS parameter (hexadeci- Meaning Solution mal) Byte 0 Byte 1 Byte 2 Byte 3 Error in the header, length or number of Correct the length and number of parame- parameter blocks ter blocks, see Figure A-20 Header infor-...

- Page 125 Parameter data records A.4 Parameter assignment and structure of the parameter data record for cam control operating mode Error code in the STATUS parameter (hexadeci- Meaning Solution mal) Byte 0 Byte 1 Byte 2 Byte 3 Difference of cam end position and cam The hysteresis setting must satisfy the start position invalid following conditions:...