Advertisement

Available languages

Available languages

Quick Links

Cross Reference

Old Part #

Q345A1008

Q345A1016

Q345A1024

Q345A1065

Q345A1156

Q345A1305

Q345A1313

Q345A1321

Q345A1446

Q345A1701

Q345A1750

Q345A1818

Q345A2030

Q345A2055

Q345A2196

Q345A2360

Q345A2386

Q345A2402

Q345A2816

Q345A2824

Q345AFA

Q345AFB

Q345AFK

Q345AKB

Q345ALA

Q345ALB

Q345U1005

3

4

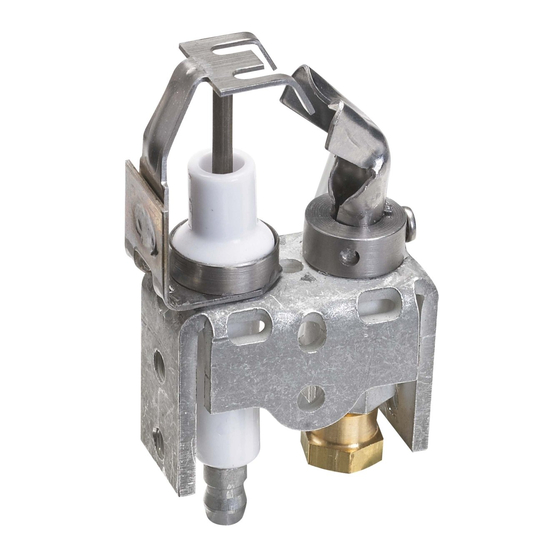

Mount Pilot Burner

Use the included screws to mount the Pilot Burner. Use the

See Cross Reference for orifice and sizes.

Auxiliary Mounting Bracket if needed.

Position the Pilot Burner so the pilot flame is aimed at the

main burner exactly the same way as the original pilot

burner flame.

Cut off the old compres-

sion fitting and replace

with the new compres-

sion fitting provided with

the new pilot burner.

TOO LOW

TOO HIGH

Never use the old com-

pression fitting because

it might not provide a

ORIGINAL

gas-tight seal.

LOCATION

MCR33962

WaRNING

FIRE OR EXPLOSION HaZaRD. CaN CaUSE

PROPERTY DaMaGE, SEVERE INJURY, OR DEaTH.

FIRE OR EXPLOSION HaZaRD. CaN CaUSE

PROPERTY DaMaGE, SEVERE INJURY, OR

Pilot burner flame alignment to the main burner is critical

DEaTH.

to safe appliance operation. Carefully read all installation

instructions. Replace only those pilots listed in the

Orifice must be the same size as the original orifice.

literature.

(Use only as a replacement for these Honeywell pilots)

Key

†

Compression

Set Hood

Use Orifice

Bracket

Fitting

L

Orange Bag

1/4 in.

No

Set Hood To

L = 20° Left

F = Front

L

Gray Bag

1/4 in.

No

R = 20° Right

F

Orange Bag

1/4 in.

No

Use Orifice

As Shipped = BCR-20 (0.020 in)

F

Orange Bag

1/4 in.

Yes

Natural gas

F

As Shipped

1/4 in.

No

Orange Bag = BCR-18 (0.018 in.)

F

Orange Bag

1/4 in.

*

Natural gas

L

Orange Bag

1/4 in.

*

Gray Bag = BBR-12 (0.012 in.) LP gas

Red Bag = BBR-11 (0.011 in.) LP gas

R

Orange Bag

1/4 in.

*

L

Red Bag

1/4 in.

Yes

†

Colors refer to the color of the label

F

Orange Bag

1/4 in.

No

on the bag.

F

Orange Bag

1/8 in.

No

*

Check Application

L

Orange Bag

1/8 in.

No

L

As Shipped

1/4 in.

No

F

As Shipped

1/4 in.

No

L

As Shipped

1/4 in.

Yes

L

Orange Bag

1/4 in.

No

L

Red Bag

1/4 in.

No

L

As Shipped

1/4 in.

No

L

Orange Bag

1/4 in.

No

L

Gray Bag

1/4 in.

No

F

*

*

Yes

F

*

*

No

F

*

*

No

R

*

*

No

L

*

*

Yes

L

*

*

No

*

*

*

*

5

Install the Correct Orifice

Connect the Ignition

and Compression Fitting

Cable and Ground Wire

Orifice

Compression fitting

(1/4 in. or 1/8 in.;

check application)

WaRNING

NOTE: Connect ground wire if present or applicable.

Note

FIRE OR EXPLOSION HaZaRD. CaN CaUSE

This pilot replaces only Honeywell standard single-rod,

PROPERTY DaMaGE, SEVERE INJURY, OR DEaTH.

hood-style intermittent pilot burners that do not have an

Follow these warnings exactly:

integral ignition and sensing wire.

1.

Disconnect power supply before wiring to prevent electrical

It will not replace batwing style pilot burners or pilot burn-

ers that have an integral ignition wire or standing pilot

shock or equipment damage.

burners.

2.

To avoid dangerous accumulation of fuel gas, turn off gas

supply at appliance service valve before starting installa-

•

For batwing-style intermittent pilot burners see the

tion and perform Gas Leak Test after completion of instal-

Q348U.

lation.

•

For hood-style intermittent pilot burners with an inte-

3.

Do not bend pilot tubing within 3 inches of the gas control

gral ignition wire see the Q3451U.

or pilot burner after compression nut has been tightened.

Gas leakage at the connection can result.

•

For standing pilot applications with standard hood-

Follow the appliance manufacturer instructions, if available;

style pilot burners see the Q314U.

otherwise, use the instructions provided.

1

The specifications given here do not include normal manu-

facturing tolerances. Therefore, this unit may not exactly

match the listed specifications.

This product is tested and calibrated under closely

controlled conditions, and some minor differences in

performance should be expected if those conditions are

A

Make sure gas is shut off.

changed.

WHEN INSTaLLING THIS PRODUCT...

B

Remove old Pilot Burner, including the old compres-

sion fitting.

1.

Read these instructions carefully. Failure to follow

instructions can damage equipment or cause a hazard-

C

Match the old model number to the Cross Reference.

ous condition.

D

Use the information in the Cross Reference to install

2.

Check cross reference in the installation guide or box to

the Pilot Burner.

verify the pilot is suitable for your application.

3.

Installer must be a trained, experienced service techni-

cian.

4.

After completing installation, use these instructions to

check out product operation.

6

7

Gas Leak Test and

Checkout

Gas Leak Test

The pilot flame should envelop 3/8 to 1/2 in. (10 to 13 mm) of

the igniter-sensor tip.

A

Make sure warning card has been removed from the pilot.

B

Turn on gas supply.

A

Turn off the system.

C

Use a gas sniffer* or paint the pipe connections upstream

B

Disconnect the lead to the MV terminal on the gas control.

of the pilot burner with a rich soap and water solution to

C

Light the pilot by setting the thermostat above room tem-

check for leaks. Bubbles indicate a gas leak.

perature to call for heat.

D

If a leak is detected, tighten the pipe connections.

D

Remove the pilot adjustment cover screw from the gas

E

Stand clear of the main burner while lighting to prevent

control.

injury from hidden leaks, which can cause flashback in the

E

Turn the inner pilot adjustment screw clockwise to

appliance vestibule.

decrease or counterclockwise to increase the pilot flame.

F

Set the thermostat to call for heat to light the main burner.

F

Replace the pilot adjustment cover screw and tighten firm-

G

With the main burner in operation, paint the pipe joints

ly after adjustment is complete to ensure proper operation.

(including the adapters) and gas control inlet and outlet

with rich soap and water solution or use a gas sniffer* to

NOTE: If Pilot flame is too small and cannot be adjusted to a

check for leaks.

larger size, a larger orifice may be needed. Check application

H

If another leak is detected, tighten the adapter screws,

requirements. If Pilot flame is too large and cannot be adjusted

joints, and pipe connections.

to a smaller size, a smaller orifice may be needed. Check appli-

I

Replace the part if the leak cannot be stopped.

cation requirements.

J

Do not proceed until all gas leaks are eliminated.

*

See AHRI video for proper use and considerations when

using an electronic gas sniffer

Checkout

Cycle the furnace through several cycles to ensure proper

smooth light off.

WaRNING

FIRE OR EXPLOSION HaZaRD. CaN CaUSE

PROPERTY DaMaGE, SEVERE INJURY, OR DEaTH.

FIRE OR EXPLOSION HaZaRD. CaN CaUSE

PROPERTY DaMaGE, SEVERE INJURY, OR DEaTH.

Using the incorrect orifice or pilot hood can cause an

unstable pilot, too large or too small of a pilot, pilot out-

Check for gas leaks any time work is done on a gas

age, reduced pilot life, improper lightoff, or gas buildup.

system.

2

Set the Hood

WaRNING

See Cross Reference for position.

a

B

Remove the Old Pilot

Burner

WaRNING

FIRE OR EXPLOSION HaZaRD. CaN CaUSE

PROPERTY DaMaGE, SEVERE INJURY, OR DEaTH.

Pilot flame must be positioned in the exact same posi-

tion with respect to the main burner. The screw must be

installed through the pilot hood and into the spud, so

the head of the screw is flush with the adapter. Failure

to properly orient the pilot flame and/or secure the pilot

hood may create an explosion hazard.

adjust Pilot Flame

For additional information and a full-length product data

document, scan this QR code or to go

www.customer.honeywell.com/universalpilot1.

automation and Control Solutions

Honeywell International Inc.

1985 Douglas Drive North

Golden Valley, MN 55422

Honeywell Ltd

705 Montrichard Avenue

Saint-Jean-sur-Richelieu, Québec

J2X 5K8

WaRNING

http://customer.honeywell.com

® U.S. Registered Trademark.

© 2013 Honeywell International Inc.

69-2755EF—03 M.S. Rev. 06-13

Printed in U.S.A.

SET HOOD

SET HOOD

RIGHT

LEFT

C

SET HOOD

FRONT

MCR34028

Advertisement

Summary of Contents for Honeywell Q345U

- Page 1 Set the Hood Note Cross Reference WaRNING (Use only as a replacement for these Honeywell pilots) FIRE OR EXPLOSION HaZaRD. CaN CaUSE This pilot replaces only Honeywell standard single-rod, PROPERTY DaMaGE, SEVERE INJURY, OR DEaTH. hood-style intermittent pilot burners that do not have an †...

- Page 2 Réglage de la coiffe Remarque Correspondances aVERTISSEMENT (utiliser uniquement pour remplacer ces veilleuses Honeywell) Cette veilleuse remplace uniquement les veilleuses RISQUE D’INCENDIE OU D’EXPLOSION. PEUT CaUSER DES DÉGÂTS ET DES BLESSURES GRaVES, intermittentes à coiffe et à tige unique sans allumage Légende...